Global Leading Diamond Tool Manufacturer.

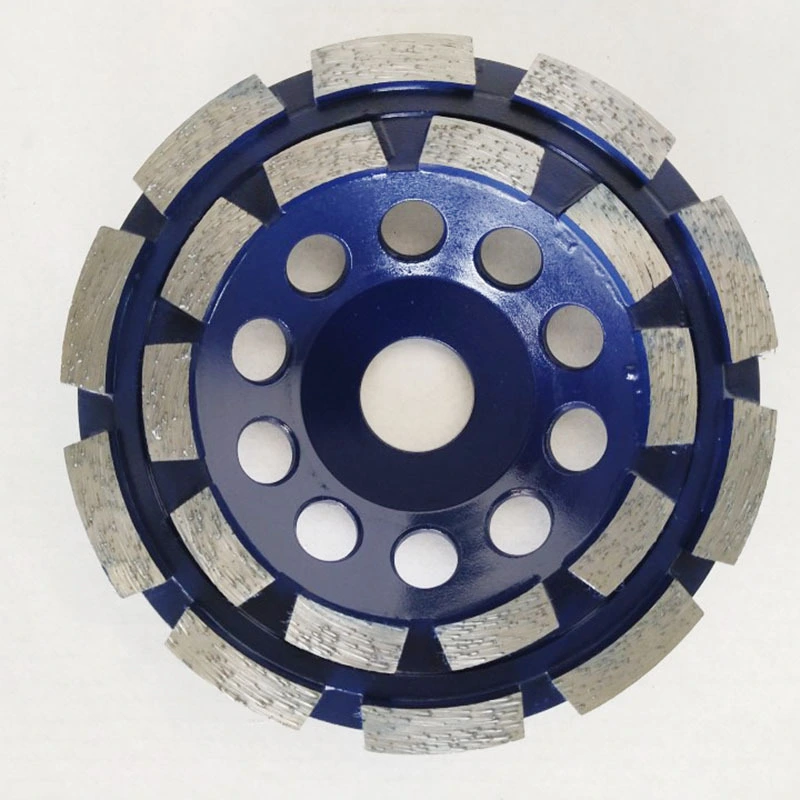

Johnson Tools 4.5inch sintered diamond grinding cup wheel double row for concrete grinding abrasive tools

Specifications:

Blade Diameter: 4"/105mm, 4.5'/115mm, 5"/125mm,7"/180mm, 9"/230mm

Arbor Size: 22.23mm, 5/8"-11, M14

Segment Thickness: 5mm

Color: Customized

Grit size: #16/20, #30/40, #50/60, #60/80, #100/120

Bonding Agent:Metal Bond

Cutting Materials: For granite,marble,concrete products,masonry,construction materials,and all types of natural stones.

Usage: Dry or wet use

Get In Touch With Us

PRODUCT ADVANTAGES

Our customer service team is a dedicated, hard-working group specially selected for their enthusiasm and commitment to providing excellent customer service. They offer advice, answer any queries.

PRODUCT parameter

product usage

- Concrete: Diamond grinding cup wheels are commonly used for grinding and smoothing concrete surfaces, including floors and countertops.

- Granite and Marble: These cup wheels are effective for shaping and polishing hard natural stones like granite and marble.

Noteworthy Features:

- Engineered Stone: They can also be used on engineered or composite stone materials. Masonry and Construction Materials: Grinding cup wheels are versatile and can work on various masonry materials, such as bricks, blocks, and construction stones.

Long lifespan and consistent performance.

High cutting efficiency, reducing energy consumption.

CE CERTIFICATION

CE certification is a crucial indicator of product quality and safety in the European market. Our diamond drill bits not only meet the requirements for CE certification but also provide reliable assurance to users based on compliance with European market standards.

These certifications not only validate our quality management system but also represent the trust and endorsement of customers in their choice. We will continue to strive for ongoing improvements in product quality to meet the demand for laser saw blades of high standards and quality from our customers.

- Our customers have consistently praised the excellence of our products.

- We are confident that you too will experience the same level of satisfaction.

- Should you require any customization, please do not hesitate to contact us.

- As the leading manufacturer of diamond tools, we are committed to providing you with the best solution possible.

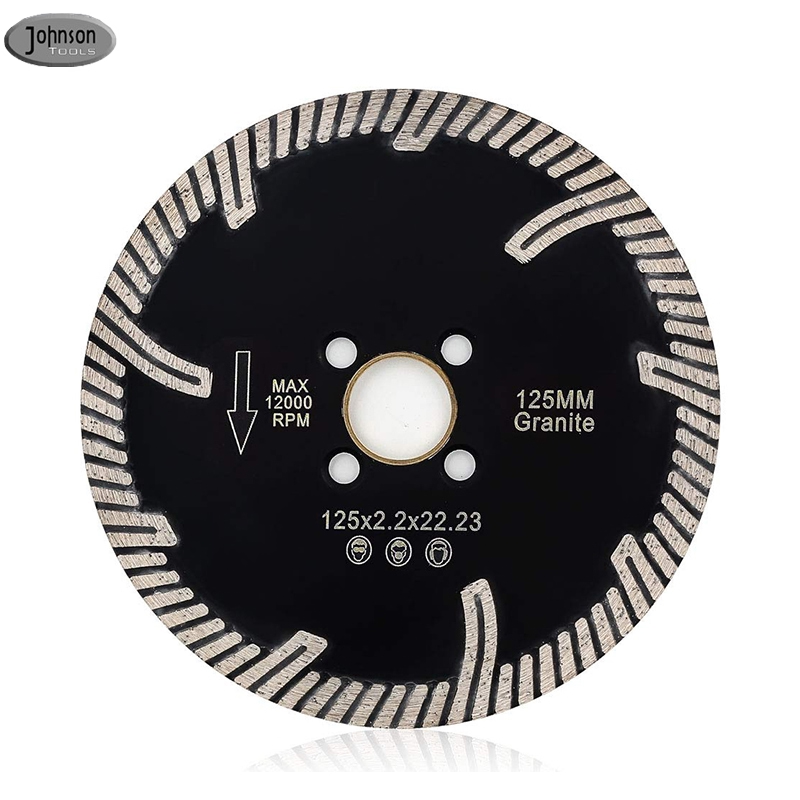

RELATED PRODUCTS

Recommend more related products for you, you can choose the right product for supporting purchases