Global Leading Diamond Tool Manufacturer.

Customized Diamond Tool Supplier Factory for Apartment

Company Advantages

· The production of johnsontools diamond tool supplier strictly complies with ISO standard manufacturing processes.

· This product meets customers' expectations for functionality, reliability and durability.

· The product is popular in domestic and foreign market and has remarkable market potential.

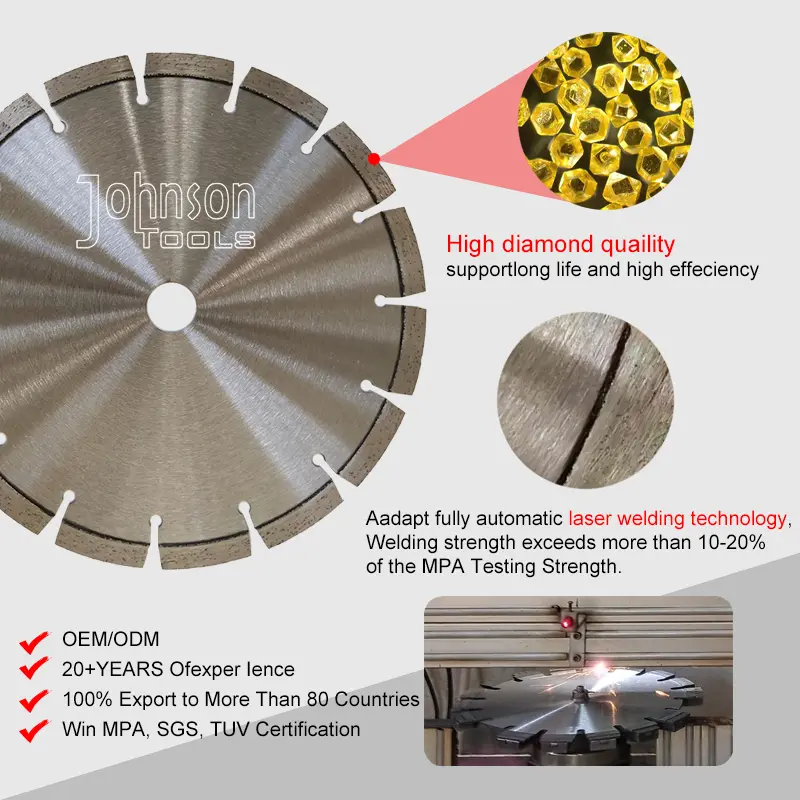

PRODUCT ADVANTAGES

Our customer service team is a dedicated, hard-working group specially selected for their enthusiasm and commitment to providing excellent customer service. They offer advice, answer any queries.

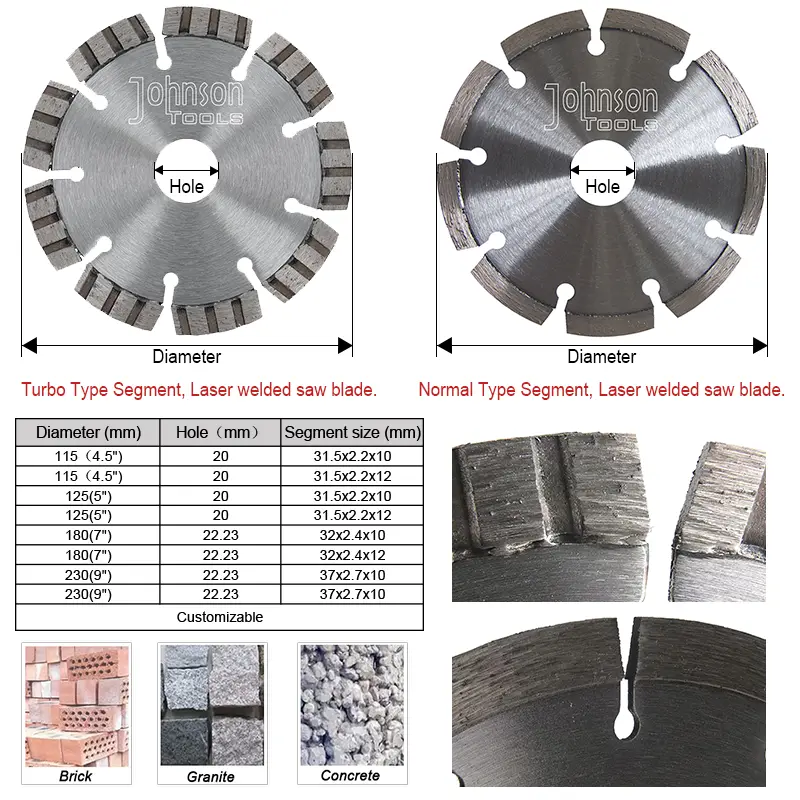

PRODUCT parameter

| Diameter | Segment Thickness | Segment Number | Center Hole | RPM |

| 4"/105mm | 2.2mm | 8 | 20mm | 14600 |

| 4.5"/115mm | 2.2mm | 8 | 20mm | 13300 |

| 5"/125mm | 2.2mm | 9 | 20mm | 12000 |

| 7"/180mm | 2.4mm | 14 | 22.23mm | 8500 |

| 9"/230mm | 2.6mm | 16 | 22.23mm | 6600 |

| Speical specification can be done as your request. | ||||

product usage

Best General Purpose Diamond saw blade

Johnson Tools Laser Diamond Blade, the best general-purpose saw blade.

This is the top choice for professional tradesmen, offering the best value for money, longest lifespan, and fastest cutting speed in its class.

This professional all-rounder, laser-welded blade, is suitable for a wide range of construction materials. It efficiently cuts various materials on appropriate angle grinders and handheld circular saws. It is undeniably the best general-purpose saw blade.

Our customers have consistently praised the excellence of our products. We are confident that you too will experience the same level of satisfaction. Should you require any customization, please do not hesitate to contact us. As the leading manufacturer of diamond tools, we are committed to providing you with the best solution possible.

MPA CE certificatation

Our company has consistently upheld a rigorous approach to the quality of laser saw blades, and we have obtained several international certifications, including MPA (German Materials Research Association) and CE certification. These certifications serve as a testament to the outstanding performance and high-quality manufacturing of our products.

MPA certification involves stringent testing in specialized laboratories in Germany, covering various performance indicators of laser saw blades, including cutting speed, wear resistance, safety, and more. Achieving MPA certification signifies that our products meet international standards in both quality and performance.

CE certification is a crucial indicator of product quality and safety in the European market. Our laser saw blades not only meet the requirements for CE certification but also provide reliable assurance to users based on compliance with European market standards.

These certifications not only validate our quality management system but also represent the trust and endorsement of customers in their choice. We will continue to strive for ongoing improvements in product quality to meet the demand for laser saw blades of high standards and quality from our customers.

cUTTING PERFORMANCE

Cutting test, as shown in the left video, adopted a 115mm diameter laser saw blade, with a handheld cutting machine featuring 1250W power and 1100RPM speed. Other testing tools included a vernier caliper and stopwatch, with the cutting material being a 0.64m wide, medium-hardness granite.

Test results revealed a cutting speed of 20 seconds per meter, consuming 0.5mm of the blade, capable of completing the cutting of 20 blocks of granite. The entire cutting process was conducted in a dry-cutting. From the data, it can be observed that the blade achieves fast cutting on medium-hard granite.

Cutting Speed: Efficient cutting speed, saving time and costs.

Surface Smoothness: The smoothness of the surface after cutting is crucial for certain projects. The laser blade ensures precise cutting, guaranteeing a smooth surface without burrs, reducing the need for subsequent finishing work.

Frequently Asked Questions

RELATED PRODUCTS

Recommend more related products for you, you can choose the right product for supporting purchases

Company Features

· Johnson Tools Manufactory Co.,Ltd has excellent performance in diamond tool supplier industry.

· Almost all defected diamond tool supplier can be checked out by our QC. There is strict QC procedure to ensure no defected diamond tool supplier. Our QC will check every detail and ensure no quality problem for all diamond tool supplier.

· In order to be number one, our company serves our customers with responsible and shared value creation. Get more info!

Application of the Product

Johnson Tools's diamond tool supplier is widely used in the industry and is widely recognized by customers.

With a focus on customers' potential needs, Johnson Tools has the ability to provide one-stop solutions.

Product Comparison

Compared with similar products, the diamond tool supplier of Johnson Tools is more strict in the selection of raw materials. The specific aspects are as follows.

Enterprise Advantages

Johnson Tools has a group of professional production and processing personnel to continuously improve the production and processing capabilities of 金刚石锯片.

Our company carries out the service model of 'standardized system management, closed-loop quality monitoring, seamless link response, and personalized service'. In this way, we can provide comprehensive and all-around services for consumers.

Based on honesty, Johnson Tools advances with the times and develops by innovations. Relying on technological innovation and talents, we strive to meet customers' needs as much as possible and provide customers with better products and services.

Since the establishment in Johnson Tools has adhered to independent innovation and actively seized opportunities, so as to achieve our own rapid and good development.

We cooperate with many foreign companies, and get recognition from partners and customers for innovative ideas, excellent quality and perfect testing system.