MPA, CE CERTIFICATION

Global Leading Diamond Tool Manufacturer.

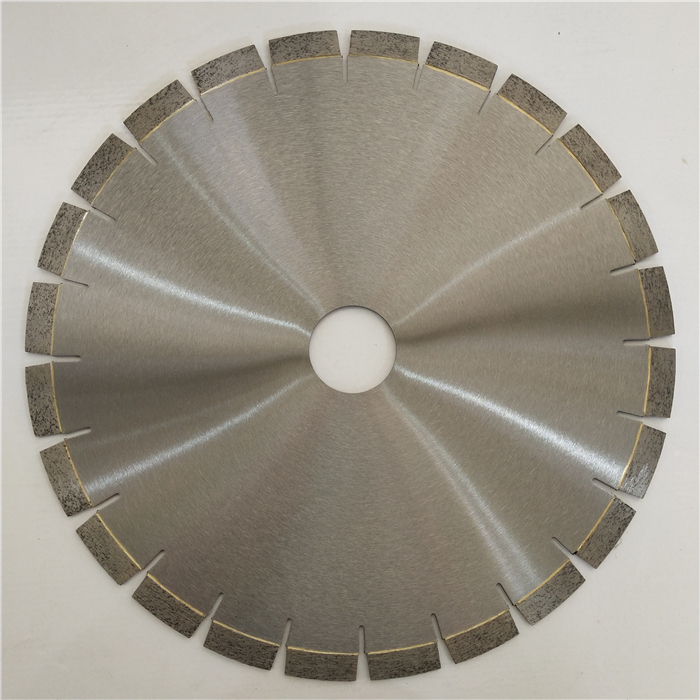

Johnson Tools 14'' High Frequency Welded Diamond Saw Blade for Cutting Granite

Specification:

The Johnson Tools 14-Inch Granite Blade is the workhorse for stone fabrication shops. Engineered specifically for cutting Hard Granite and engineered stone, this blade utilizes advanced High Frequency Welding (Copper Welding) technology to ensure a secure bond between the segments and the core. It features an industry-leading 15mm Segment Height, providing 30%-50% more cutting life than standard blades, making it the most cost-effective choice for production environments.

Technical Specifications:

-

Diameter: 14 Inch (350mm).

-

Segment Size: 40mm (L) x 3.5mm (T) x 15mm (H).

-

Arbor/Bore: 50mm / 60mm (Standard for Bridge Saws).

-

Technology: High Frequency Welded (Copper Bond).

-

Application: Granite, Hard Stone, Concrete.

-

Cutting Method: Wet Cutting (Recommended).

Get In Touch With Us

PRODUCT ADVANTAGES

Our customer service team is a dedicated, hard-working group specially selected for their enthusiasm and commitment to providing excellent customer service. They offer advice, answer any queries.

product usage

Coolant or Water Usage:

Consider using a coolant or water during cutting operations. This helps in dissipating heat generated during the cutting process, enhancing the lifespan of the blade and preventing overheating.

Safety Measures:

Adhere to safety guidelines and wear appropriate personal protective equipment (PPE) such as safety glasses, hearing protection, and gloves. Follow safety protocols to minimize the risk of injury during cutting operations.

🛠️ Professional Grade Laser Saw Blade, Effortless and Efficient Cutting 🛠️

Our customers have consistently praised the excellence of our products. We are confident that you too will experience the same level of satisfaction. Should you require any customization, please do not hesitate to contact us. As the leading manufacturer of diamond tools, we are committed to providing you with the best solution possible.

Our laser saw blades passed quality standards with MPA and CE certifications, ensuring international compliance.

MPA certification involves testing in specialized German laboratories, covering cutting speed, wear resistance, and safety.

CE certification signifies adherence to European market standards, providing users with reliable assurance.

These certifications affirm our commitment to quality and customer trust. We will persist in enhancing product quality to meet the high standards and demand for top-notch laser saw blades from our customers.

RELATED PRODUCTS

Recommend more related products for you, you can choose the right product for supporting purchases