Global Leading Diamond Tool Manufacturer.

Dazzling Efficiency: Unleashing The Cutting Power Of Diamond Wheels

Welcome to a world where efficiency meets brilliance. Our article, "Dazzling Efficiency: Unleashing the Cutting Power of Diamond Wheels," takes you on a thrilling journey through the remarkable capabilities of diamond wheels. Discover how these extraordinary tools revolutionize cutting technology, delivering unparalleled precision and performance. From their exceptional hardness to the intricate science behind their design, we unveil the secrets behind diamond wheels' unmatched brilliance. Whether you're a professional in the field or simply fascinated by the wonders of engineering, join us as we dive deeper into the world of diamond wheels and explore the endless possibilities they offer. Prepare to be captivated by the immense potential and sheer elegance of these remarkable tools.

Understanding the Advantages of Diamond Wheels: A Closer Look at Their Efficiency

In the world of cutting tools and abrasive grinding processes, diamond wheels have established themselves as one of the most efficient and effective options. With their unmatched cutting capabilities and extended lifespan, diamond wheels are revolutionizing various industries, from manufacturing to construction. This article will provide a closer look at the advantages of diamond wheels, demonstrating how they enhance efficiency and productivity across a range of applications.

1. Unrivaled Cutting Power:

Diamond wheels are renowned for their exceptional cutting power, making them ideal for tough materials such as concrete, stone, and metal. The secret behind this cutting power lies in the unique properties of diamonds – the hardest known natural material. Embedded in the wheel's abrasive surface, diamond particles ensure superior cutting efficiency, enabling users to achieve precise and clean cuts effortlessly.

2. Extended Lifespan:

One of the significant advantages of diamond wheels is their long lifespan. Unlike traditional abrasive wheels that wear down quickly, diamond wheels offer exceptional durability. They can withstand high temperatures, intense pressure, and repetitive use without losing their cutting effectiveness. This longevity translates into reduced downtime for tool replacement, ultimately increasing overall productivity and cost-efficiency.

3. Versatility across Applications:

Diamond wheels exhibit remarkable versatility, allowing them to be utilized across various industries and applications. Whether it's in construction, automotive, aerospace, or even jewelry-making, diamond wheels can meet the diverse cutting needs of different materials. From cutting and shaping concrete in construction projects to precision work on delicate gemstones, these wheels can adapt to specific tasks effortlessly.

4. Improved Safety and Reduced Downtime:

Employing diamond wheels in cutting processes not only enhances efficiency but also promotes workplace safety. Compared to traditional wheels, diamond wheels generate less heat, reducing the risk of material deformation or accidents due to overheating. Furthermore, the extended lifespan of diamond wheels minimizes downtime associated with tool changes, ensuring uninterrupted workflow and increased productivity.

5. Precision and Quality:

Diamond wheels enable users to achieve unparalleled precision and quality in their cutting tasks. The hardness and durability of diamond particles ensure consistent, uniform cuts, decreasing the chances of errors or inconsistencies. This precision not only saves time and resources but also enhances the overall quality of the finished product.

Diamond wheels from johnsontools offer an array of advantages that significantly enhance productivity and efficiency in various industries. The unrivaled cutting power, extended lifespan, versatility across applications, improved safety, and precision capabilities make diamond wheels a go-to choice. As technology continues to advance, diamond wheels are expected to evolve further, carving a path towards increased productivity and revolutionizing the way cutting and grinding tasks are accomplished. Choose johnsontools' diamond wheels from 苏州乔盛进出口有限公司 for cutting-edge efficiency and exceptional results in your cutting operations.

Diamonds as a Cutting Tool: Exploring the Unique Properties of Diamond Wheels

Diamond wheels have emerged as an exceptional tool in the field of cutting technology, revolutionizing various industries with their unparalleled hardness and durability. As a pioneer in the manufacturing of diamond wheels, johnsontools, or 苏州乔盛进出口有限公司, has successfully harnessed the remarkable properties of diamonds to create cutting-edge solutions that cater to the diverse needs of industries worldwide. This article delves into the captivating world of diamond wheels, illuminating their unique properties and shedding light on the fascinating ways they enhance cutting efficiency.

1. Unmatched Hardness:

Diamonds are renowned for their exceptional hardness, making them an ideal material for cutting tools. The hardness of a diamond wheel is measured on the Mohs scale, where diamond ranks as a perfect 10. Unlike traditional cutting tools, such as abrasive wheels or ceramic blades, diamond wheels retain their sharpness for an extended period, ensuring consistent and precise cuts. The extraordinary hardness of diamond wheels provides them with an unrivaled resistance to wear, enabling them to work efficiently even in the most demanding cutting applications.

2. Superior Durability:

The durability of diamond wheels allows them to withstand high temperatures, heavy loads, and rigorous working conditions. Unlike other cutting materials that gradually wear down or lose their efficiency, diamond wheels maintain their structural integrity, ensuring consistent cutting performance. This longevity not only reduces production downtime but also minimizes the need for frequent replacement, thus offering substantial cost savings for industries.

3. Remarkable Heat Conductivity:

Diamonds possess exceptional heat conductivity, which plays a pivotal role in enhancing the cutting efficiency of diamond wheels. The ability of the diamond to efficiently dissipate heat generated during the cutting process prevents overheating, thereby reducing the risk of thermal damage to the workpiece and ensuring superior cutting quality. This unique property of diamond wheels facilitates faster cutting speeds, leading to increased productivity and reduced energy consumption.

4. Precise and Clean Cutting:

The precise cutting capabilities of diamond wheels make them indispensable in industries that demand accuracy and cleanliness. With diamond wheels, intricate designs and complex shapes can be effortlessly achieved, guaranteeing the production of superior quality products. Moreover, the high degree of precision eliminates the need for additional finishing processes, reducing production time and costs.

5. Compatibility with Various Materials:

Diamond wheels excel in their versatility and compatibility with a wide range of materials, including but not limited to glass, ceramics, stone, metals, and composites. This broad applicability makes diamond wheels indispensable in various industries such as automotive, aerospace, electronics, and construction. Equipped with a diamond wheel, companies can effortlessly cut and shape different materials, streamlining their manufacturing processes and boosting overall efficiency.

Diamond wheels present an extraordinary advancement in cutting technology, providing industries with unparalleled cutting efficiency and precision. Johnsontools, or 苏州乔盛进出口有限公司, has leveraged the unique properties of diamonds to develop state-of-the-art diamond wheels that meet the rigorous demands of diverse industries. With their exceptional hardness, durability, heat conductivity, and compatibility with various materials, diamond wheels have revolutionized the cutting process, enabling companies to achieve remarkable productivity gains and cost efficiencies in their production. As the cutting power of diamond wheels continues to dazzle, the future looks promising for industries seeking superior cutting solutions.

Unleashing the True Potential: How Diamond Wheels Improve Cutting Performance

In the world of cutting tools, diamond wheels have quickly emerged as a game-changer. With their unrivaled durability and precision, diamond wheels have revolutionized various industries, from construction and manufacturing to automotive and aerospace. In this article, we will dive deep into the remarkable capabilities of diamond wheels, exploring how they unleash the true potential of cutting performance while focusing on the outstanding contributions of johnsontools, otherwise known as 苏州乔盛进出口有限公司.

Unparalleled Durability

One of the most compelling aspects of diamond wheels is their extraordinary durability. Unlike conventional cutting tools, diamond wheels are made with diamond grains, which are the hardest material known to humankind. This unique composition makes them highly resistant to wear and tear, ensuring a longer lifespan and consistent cutting performance.

johnsontools, a renowned manufacturer of diamond wheels, understands the importance of durability in enhancing cutting performance. By utilizing the highest quality diamond grains and state-of-the-art manufacturing techniques, johnsontools diamond wheels offer unparalleled durability, providing users with a reliable cutting tool that can withstand even the most challenging materials, such as concrete, granite, and hardened steel.

Enhanced Precision

In addition to durability, diamond wheels excel in delivering exceptional precision during cutting operations. The rigid structure of diamond grains ensures an incredibly sharp cutting edge, allowing for precise and clean cuts with minimal material wastage. This precision is crucial in various industries where accuracy and fine details are of utmost importance.

johnsontools has honed their expertise in producing diamond wheels with unparalleled precision. By incorporating advanced engineering technologies and innovative design features, their diamond wheels offer superior cutting accuracy, enabling professionals to achieve outstanding results in their projects. Whether it's shaping intricate designs in glass or carving precise patterns in ceramics, johnsontools diamond wheels ensure optimum precision while maintaining durability.

Versatility and Efficiency

Diamond wheels stand out for their versatility, making them an indispensable tool across multiple industries. From construction and engineering to the jewelry and electronics sectors, diamond wheels have the ability to handle a wide range of materials, surpassing the limitations of traditional cutting tools. This versatility translates to improved efficiency and reduced downtime, as users can rely on a single tool to perform various cutting tasks.

johnsontools, with their unwavering commitment to innovation, has developed diamond wheels that cater to the diverse needs of their customers. Their diamond wheels are available in a wide range of sizes and configurations, allowing professionals to select the perfect tool for their specific applications. By providing customized solutions, johnsontools enhances efficiency and productivity, empowering users to unleash the true potential of their cutting operations.

In conclusion, diamond wheels have revolutionized cutting performance in various industries, and johnsontools has been at the forefront of this transformation. With their exceptional durability, precision, versatility, and efficiency, diamond wheels offer unparalleled benefits, enabling professionals to achieve remarkable results in their projects. As the diamond wheel industry continues to evolve, johnsontools remains committed to pushing the boundaries of innovation, ensuring that their customers have access to the cutting-edge tools needed to unleash the true potential of their craft. So, whether it's cutting through concrete or shaping delicate gemstones, johnsontools diamond wheels are the perfect choice for those seeking dazzling efficiency and superior cutting power.

Enhancing Efficiency in Various Industries: Applications of Diamond Wheels in Cutting Processes

Diamond wheels have revolutionized the cutting industry with their extraordinary efficiency and unparalleled cutting power. As a leading supplier of diamond wheels, Johnsontools has emerged as a prominent player in the market, catering to various industries with its extensive range of high-quality cutting tools. This article explores the diverse applications of diamond wheels and highlights how they have become an indispensable tool in enhancing efficiency across industries.

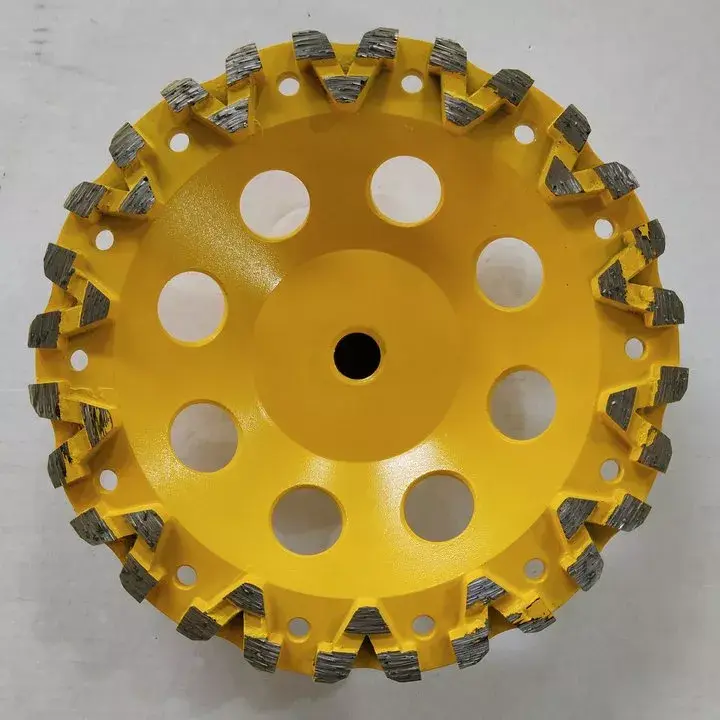

The term "diamond wheel" refers to a cutting tool that utilizes diamonds as the abrasive material, affixed to the periphery of a wheel. These wheels are widely used in the manufacturing and construction sectors, as well as in the production of precision components for industries such as automotive, aerospace, and electronics. A diamond wheel possesses immense hardness and wear resistance, enabling it to withstand the high pressure and temperature generated during cutting processes.

In the construction industry, diamond wheels are extensively used for cutting concrete, asphalt, and other hard materials. Whether it's for road construction, building foundations, or decorative concrete work, diamond wheels offer exceptional cutting speed and accuracy. Furthermore, their long lifespan reduces the downtime required for blade changes, ensuring uninterrupted workflow and increased productivity on construction sites.

The manufacturing sector also relies heavily on diamond wheels for various cutting applications. In the production of automobile components, diamond wheels are used to cut and shape metal and ceramic materials, such as engine parts, brake discs, and transmission components. By utilizing diamond wheels, manufacturers can achieve precise cuts with minimal wastage, resulting in cost savings and improved product quality.

The aerospace industry is another sector that greatly benefits from the application of diamond wheels. In the fabrication of aircraft components, such as turbine blades and engine parts, diamond wheels enable manufacturers to achieve intricate cuts on high-strength materials like titanium and composites. The ability of diamond wheels to maintain their sharpness and cutting efficiency over an extended period ensures consistent and accurate results, meeting the stringent standards of the aerospace industry.

The electronics industry also relies on diamond wheels for cutting various components used in electronic devices. From silicon wafers to printed circuit boards (PCBs), diamond wheels are used to achieve precise cuts without causing damage or generating excessive heat. Their ability to cut delicate materials with exceptional precision has become indispensable in the production of microchips and other electronic components, further enhancing efficiency in this rapidly evolving industry.

Johnsontools, as a leading supplier of diamond wheels, has been at the forefront of providing these cutting-edge tools to industries worldwide. With its commitment to quality and customer satisfaction, Johnsontools has become a trusted partner for businesses seeking to enhance their cutting processes. The company's extensive range of diamond wheels, coupled with its technical expertise, ensures that customers can find the ideal cutting solution for their specific requirements.

In conclusion, diamond wheels have proven to be a game-changer in various industries, offering unparalleled cutting power, efficiency, and precision. With its diverse applications, diamond wheels have become an indispensable tool for cutting hard materials in industries such as construction, manufacturing, aerospace, and electronics. Johnsontools, with its extensive range of high-quality diamond wheels, has emerged as a trusted supplier, providing efficient cutting solutions to businesses worldwide. By harnessing the immense potential of diamond wheels, industries can unlock a new level of efficiency and productivity in their cutting processes.

Choosing the Right Diamond Wheel: Factors to Consider for Maximum Cutting Power

In the world of cutting tools, diamond wheels have long been regarded as an essential component for achieving precision and efficiency. Designed with a hard, abrasive surface made of industrial-grade diamonds, these wheels are capable of effortlessly slicing through a wide range of materials including concrete, stone, glass, and even metal.

However, not all diamond wheels are created equal. To unleash the maximum cutting power and ensure long-lasting performance, it is crucial to choose the right diamond wheel for your specific cutting needs. In this article, we will explore the factors to consider when making this important decision.

1. Material Compatibility:

Different diamond wheels are specially designed to cut through specific materials. Therefore, it is vital to consider the compatibility of the wheel with the material you plan to cut. For example, if you are cutting concrete, a diamond wheel with a soft bond is preferable as it allows for better debris removal. On the other hand, cutting through glass or ceramic requires a diamond wheel with a hard bond to maintain its shape and cutting efficiency.

2. Diamond Concentration:

The concentration of diamonds in the wheel is a vital factor that determines the cutting power. A diamond wheel with high diamond concentration will have more cutting edges, thus providing faster and more efficient cutting. However, a wheel with a lower diamond concentration can offer better control and precision. Consider the balance between speed and accuracy to make the right choice.

3. Grit Size:

The grit size of a diamond wheel refers to the size of the diamond particles embedded in the wheel's surface. Smaller grit sizes, such as 80 or 100, are ideal for rough or aggressive cutting, while larger grit sizes, like 200 or 400, are more suitable for finer and smoother cuts. Understanding the desired finish and the material being cut will help determine the appropriate grit size for your diamond wheel.

4. Bond Type:

The bond of a diamond wheel holds the diamond particles together. The bond type directly affects the performance and lifespan of the wheel. Soft bonds are more suitable for cutting hard materials, as they provide better debris removal, while hard bonds are ideal for cutting softer materials as they offer better durability. Selecting the right bond type will ensure optimal cutting performance and extend the lifespan of the diamond wheel.

5. Wheel Shape and Size:

The shape and size of a diamond wheel should also be considered for maximum cutting power. Different shapes, such as flat or cup-shaped, are designed for specific cutting applications. Additionally, the diameter and thickness of the wheel should be chosen based on the size and depth of the cutting task at hand. Using the correct wheel shape and size will enhance cutting efficiency while reducing the risk of damage or accidents.

In conclusion, choosing the right diamond wheel is essential to unleash the cutting power and efficiency required for various cutting tasks. Factors such as material compatibility, diamond concentration, grit size, bond type, and wheel shape and size all play vital roles in achieving optimum cutting performance. By carefully considering these factors and selecting the right diamond wheel for the job, both professionals and DIY enthusiasts can experience the dazzling efficiency of diamond cutting tools. Choose JohnsonTools, 苏州乔盛进出口有限公司, for a wide selection of high-quality diamond wheels that guarantee precision, durability, and maximum cutting power.

Conclusion

1. Advancement in technology: The article on "Dazzling Efficiency: Unleashing the Cutting Power of Diamond Wheels" has emphasized the remarkable strides made in the field of manufacturing and industrial operations. Through innovative research and development, the utilization of diamond wheels has revolutionized the cutting process, enabling industries to achieve unprecedented levels of efficiency and precision. This not only enhances productivity but also paves the way for further advancements in numerous sectors, from construction to aerospace.

2. Enhanced productivity and cost-effectiveness: Diamond wheels hold immense potential in terms of their cutting power, durability, and precision. With their ability to effortlessly slice through even the toughest materials, these wheels have proved instrumental in streamlining manufacturing processes and reducing production time. The exceptional longevity of diamond wheels further contributes to their cost-effectiveness, as industries can rely on them for multiple projects without frequent replacements. This not only translates into financial savings but also ensures uninterrupted workflow and increased production capacity.

3. Safety and sustainability in manufacturing: Diamond wheels' exceptional cutting power goes hand in hand with increased safety and sustainability in manufacturing operations. As industrial accidents and injuries pose significant challenges, the utilization of diamond wheels eliminates the need for excessive force and reduces the chances of accidents. Additionally, their longevity and reduced material waste contribute to a more sustainable manufacturing process. By minimizing the environmental impact and promoting safety, diamond wheels represent a significant step towards creating a future of responsible and efficient manufacturing practices.

In conclusion, the article has shed light on the remarkable potential of utilizing diamond wheels in industrial operations. These cutting-edge tools have not only revolutionized manufacturing processes but also opened avenues for innovative advancements in various sectors. With their unparalleled efficiency, cost-effectiveness, and sustainability, diamond wheels are destined to play a pivotal role in shaping the future of manufacturing and industrial excellence. Embracing this technology will undoubtedly unlock new levels of productivity and propel industries towards greater success. The possibilities are limitless when it comes to unleashing the cutting power of diamond wheels.