Global Leading Diamond Tool Manufacturer.

Dazzling Efficiency: Unveiling The Brilliant Advancements Of Diamond Wheels

Welcome to our latest article, where we dive into the mesmerizing world of diamond wheels and unravel the fascinating advancements that have revolutionized various industries. Prepare to be awed by the dazzling efficiency these remarkable tools possess, as we take you on a journey through their extraordinary capabilities and the immense impact they have made. Join us as we uncover the brilliant advancements of diamond wheels, showcasing their unrivaled potential and the evolution they have brought to the realm of cutting-edge technology. Whether you are a curious enthusiast or an industry expert craving for insights, this article promises to captivate and educate, leaving you eager to explore further into the enthralling world of diamond wheels.

The Evolution of Diamond Wheels: From Traditional to Cutting-Edge Technology

Diamond wheels have been an essential tool in various industries, including construction, fabrication, and manufacturing. Over the years, these indispensable tools have undergone remarkable transformations, evolving from traditional wheels to cutting-edge technology. In this article, we will delve into the revolutionary advancements that have propelled diamond wheels into the forefront of efficiency and performance.

1. Understanding the Diamond Wheel:

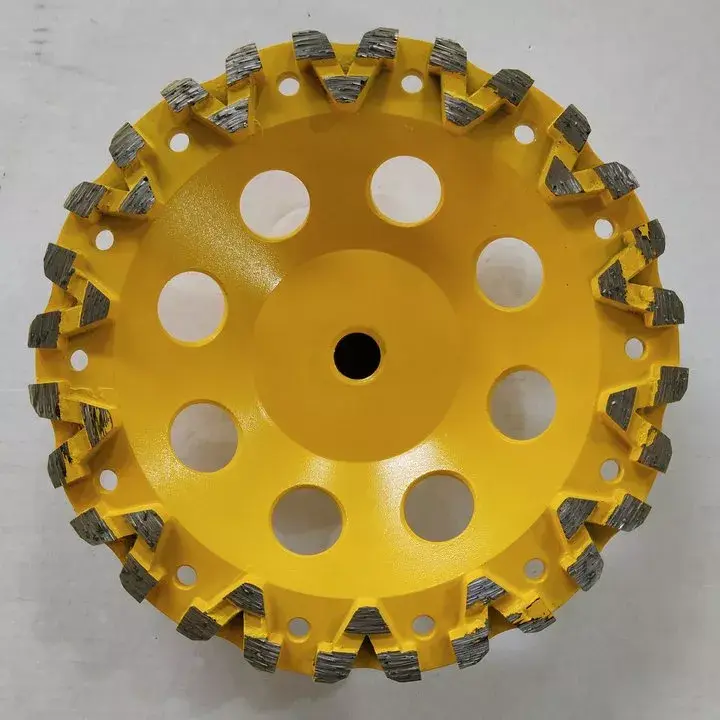

Diamond wheels consist of a central core made from steel, aluminum, or composite materials, embedded with industrial-grade synthetic diamonds. These robust tools are used for cutting, grinding, and polishing a wide range of materials, including concrete, stone, ceramics, glass, and metals. The high hardness and abrasion resistance of diamond particles make these wheels incredibly efficient and long-lasting.

2. Traditional Diamond Wheels:

Traditional diamond wheels were primarily manufactured using a sintering process, where diamond particles were bound together with metal or resin bond to form the working surface. While these wheels were effective to some extent, they had limitations concerning cutting speed, precision, and lifespan. The introduction of modern technologies has paved the way for transformative advancements in diamond wheel manufacturing.

3. Electroplated Diamond Wheels:

One of the most significant breakthroughs in diamond wheel technology is the advent of electroplated diamond wheels. In this process, a single layer of diamond particles is bonded to the wheel's surface using an electroplating technique. This method eliminates the use of metal or resin bonds, allowing for increased cutting speeds, improved precision, and longer lifespan. Electroplated diamond wheels are highly regarded for their ability to cut through even the toughest materials with exceptional ease.

4. Vacuum Brazed Diamond Wheels:

Another revolution in diamond wheel technology comes in the form of vacuum brazed diamond wheels. Unlike traditional wheels, vacuum brazed wheels have diamond particles directly fused onto the wheel's surface using a vacuum brazing furnace. This innovative method ensures a secure bond between the diamonds and the wheel core, resulting in superior cutting performance, extended durability, and resistance to high temperatures. Vacuum brazed diamond wheels have become a go-to choice for professionals who seek precise and efficient cutting solutions.

5. Hybrid Diamond Wheels:

As technology continues to advance, cutting-edge innovations have birthed hybrid diamond wheels. These wheels combine the best elements of electroplated and vacuum brazed wheels to deliver optimal performance. Hybrid diamond wheels feature a diamond layer electroplated onto a vacuum-brazed core, offering the advantages of both techniques. These wheels excel in applications that require high precision, fast cutting speeds, and exceptional longevity.

The evolution of diamond wheels from traditional to cutting-edge technology has revolutionized various industries, propelling efficiency and performance to new heights. With advancements like electroplated, vacuum brazed, and hybrid diamond wheels, professionals can now accomplish tasks with greater precision, faster cutting speeds, and prolonged tool life. As a leading manufacturer in the industry, Johnson Tools continues to push the boundaries of diamond wheel innovation, providing customers with exceptional tools that elevate their productivity and deliver impeccable results.

Unleashing Unmatched Performance: How Diamond Wheels Excel in Various Industries

Diamond wheels have revolutionized industries with their unrivaled performance and remarkable efficiency. As one of the leading manufacturers in this field, Johnson Tools has continuously pushed the boundaries of technology to develop diamond wheels that not only deliver dazzling results but also enhance productivity across various sectors. In this article, we will delve into the brilliant advancements of diamond wheels, exploring their applications and highlighting how Johnson Tools has established itself as a trusted brand in the industry.

The versatility of diamond wheels is unparalleled, making them indispensable in a wide array of industries. Whether in the automotive sector, construction, or even healthcare, diamonds have become the go-to choice for professionals seeking cutting-edge tools. Automotive manufacturers have harnessed the power of diamond wheels for precision cutting and grinding, resulting in improved accuracy in the production of critical components. Similarly, construction companies rely on diamond wheels to tackle the toughest materials, such as concrete and stone, enabling faster and more efficient project completion.

One of the key reasons behind the exceptional performance of diamond wheels lies in the unique properties of diamonds themselves. Diamonds are the hardest known material, making them ideal for creating cutting tools that can withstand extreme pressure and abrasion. Johnson Tools harnesses this characteristic by meticulously selecting high-quality diamonds and incorporating them into their cutting-edge designs.

In addition to their unmatched durability, diamond wheels also provide superior cutting performance. The precise manufacturing process ensures that each wheel possesses the right balance of hardness, grit size, and bond strength, resulting in optimal cutting efficiency. Johnson Tools has spent years perfecting their production techniques, constantly refining their designs to provide customers with diamond wheels that enable them to achieve the highest levels of precision and productivity.

Moreover, the advancements in diamond wheel technology have not only improved their performance but have also made them more environment-friendly. With a strong focus on sustainability, Johnson Tools has implemented advanced manufacturing practices that reduce waste and enhance energy efficiency. By utilizing innovative diamond formulation and bonding techniques, their wheels are designed to minimize material consumption while maximizing performance, leading to a more sustainable and eco-conscious solution for industries worldwide.

Another noteworthy aspect of Johnson Tools' diamond wheels is their exceptional lifespan. Thanks to the high quality of the diamonds used and the precise manufacturing process, these wheels offer extended usage compared to traditional cutting tools. This translates into cost savings for businesses in the long run, as they require fewer wheel replacements, minimizing downtime and boosting productivity.

To cater to the diverse needs of different industries, Johnson Tools offers a wide range of diamond wheel variations. From segmented wheels for concrete grinding to diamond blades for cutting delicate materials, their product portfolio ensures that professionals have access to the most suitable tools for their specific requirements. With the ability to customize wheel designs based on specific applications, Johnson Tools has established itself as a reliable partner for industries seeking tailored diamond wheel solutions.

In conclusion, diamond wheels have become an integral part of various industries, providing unmatched performance and efficiency. Johnson Tools, with their commitment to excellence and innovation, has emerged as a leading brand in the manufacturing of diamond wheels. Their dedication to quality, sustainability, and customer satisfaction sets them apart from competitors, solidifying their position as the go-to choice for professionals across the globe. With the dazzling advancements in diamond wheel technology, Johnson Tools continues to empower industries and elevate their performance to new heights.

Unveiling the Secrets Behind Diamond Wheels: The Science and Engineering of Dazzling Efficiency

Diamond wheels have long been hailed as the epitome of precision and efficiency in various industries, ranging from construction to manufacturing. These innovative tools have garnered substantial attention for their ability to effortlessly cut through the toughest materials, leaving behind a remarkable finish. In this article, we will delve into the science and engineering behind the astounding efficiency of diamond wheels, exploring the secrets that make them an indispensable asset in the world of cutting and grinding.

The Role of Johnson Tools:

As a leading manufacturer in the industry, Johnson Tools has constantly pushed the boundaries of diamond wheel technology, seeking to enhance their performance and efficiency. With decades of experience and a commitment to innovation, the company has become synonymous with quality and reliability, earning the trust of businesses and professionals worldwide. Let's explore the key factors that contribute to the dazzling efficiency of Johnson Tools' diamond wheels.

Superior Diamond Grit:

One of the most crucial elements of a diamond wheel is the quality of the diamond grit embedded within it. Johnson Tools ensures that only the finest industrial-grade diamonds are utilized in their wheels. These diamonds are meticulously selected based on their size, shape, and strength. The high-quality diamond grit allows for exceptional cutting and grinding capabilities, enabling professionals to achieve precise results with minimal effort.

Revolutionary Bonding Techniques:

Johnson Tools has pioneered advanced bonding techniques that significantly enhance the efficiency of their diamond wheels. The bonding material acts as the foundation that holds the diamond grit together, providing stability during operation. By utilizing state-of-the-art technologies, such as vacuum brazing and electroplating, Johnson Tools achieves a flawless bond between the diamond grit and the wheel body. This not only improves the overall cutting performance but also extends the lifespan of the diamond wheel.

Optimized Wheel Design:

The design of the diamond wheel plays a crucial role in its efficiency. Johnson Tools invests deeply in research and development to create optimized wheel designs that maximize performance. These designs take into account factors such as wheel thickness, rim shape, and segment arrangement. By carefully engineering these aspects, the wheels are able to maintain a balanced and even distribution of pressure during operation, resulting in smoother cuts and reduced wear.

Advanced Cooling Systems:

Heat management is a vital consideration in diamond wheel efficiency. Johnson Tools incorporates advanced cooling systems into their diamond wheels to mitigate the heat generated during cutting and grinding. This prevents the wheels from overheating and maintains their cutting performance. The cooling systems can range from specially designed slots or holes in the wheel body to integrated water channels that constantly circulate cooling fluid. These innovations ensure the longevity and consistent efficiency of the diamond wheels.

The science and engineering behind diamond wheels have paved the way for astonishing advancements in efficiency, and Johnson Tools has been at the forefront of these innovations. Through superior diamond grit, pioneering bonding techniques, optimized wheel designs, and advanced cooling systems, Johnson Tools has elevated the performance of diamond wheels to dazzling heights. Professionals across various industries can rely on Johnson Tools' diamond wheels for unparalleled efficiency and precision. Embrace the brilliance of diamond wheel technology and unlock the full potential of your cutting and grinding projects.

Applications Galore: Exploring the Wide Range of Industries Benefiting from Diamond Wheels

Dazzling Efficiency: Unveiling the Brilliant Advancements of Diamond Wheels"

In the realm of cutting and grinding tools, diamond wheels have emerged as an unrivaled choice, revolutionizing various industries with their exceptional durability and efficiency. These incredible tools, embedded with diamond particles, offer exceptional performance in terms of precision, longevity, and versatility. From construction to aerospace, and from automotive to medical, diamond wheels have found their way into a wide range of industries, delivering exceptional results and fueling innovation. In this article, we will delve into the remarkable applications of diamond wheels, showcasing how they are reshaping industries and unlocking new possibilities.

Precision Engineering and Manufacturing Industries:

The precision engineering and manufacturing industries are perhaps the biggest beneficiaries of diamond wheels. With their ability to cut and shape even the toughest materials with utmost precision, these wheels have become indispensable tools in the production of intricate components. Whether it's cutting or grinding ceramics, composites, or hardened metals, diamond wheels provide unmatched accuracy and a superior finishing touch. From the creation of delicate instruments to high-quality jewelry manufacturing, diamond wheels enable craftsmen to execute their designs flawlessly.

Construction and Architectural Industries:

The construction and architectural sectors have witnessed a significant transformation with the advent of diamond wheels. These tools have become the go-to choice for tasks such as cutting, shaping, and polishing various construction materials including concrete, granite, and natural stones. The use of diamond wheels in these industries ensures precise cuts, reducing the overall time and effort required for construction projects. Moreover, their ability to smoothen rough surfaces and deliver a pristine finish has significantly enhanced the aesthetic appeal of architectural designs.

Automotive and Aerospace Industries:

In the automotive and aerospace industries where precision, efficiency, and durability are of utmost importance, diamond wheels have become indispensable. These industries rely on intricate and precise cuts for manufacturing components such as engine parts, turbine blades, and carbon fiber composites. Diamond wheels excel at cutting hardened materials like carbide and ceramic, ensuring the highest levels of precision and longevity. Additionally, their exceptional cooling properties prevent overheating, making them ideal for long hours of continuous use in demanding applications.

Medical and Dental Industries:

Diamond wheels have also made significant advancements in the medical and dental fields, where precision and accuracy are paramount. These industries heavily rely on diamond wheels for tasks like cutting, shaping, and finishing orthopedic implants, surgical instruments, and dental prosthetics. The exceptional hardness and sharpness of diamond particles allow precise and clean cuts, minimizing the risk of infections and complications. The use of diamond wheels in these industries ensures the highest quality standards and contributes to better patient outcomes.

Diamond wheels, with their unparalleled precision and efficiency, have revolutionized numerous industries, transcending conventional cutting and grinding methods. Their vast applications in precision engineering, construction, automotive, aerospace, and medical industries have not only streamlined processes but have also unlocked new possibilities for innovation. As the demand for quality and precision continues to rise, the significance of diamond wheels in various industries cannot be overstated. Johnson Tools, as a leading manufacturer and provider of diamond wheels, continues to drive advancements in this field, empowering industries with the tools they need to achieve remarkable results and stay ahead of the competition.

Investing in Brilliance: The Economic and Environmental Advantages of Diamond Wheels

Dazzling Efficiency: Unveiling the Brilliant Advancements of Diamond Wheels"

Diamond wheels have long been hailed as the epitome of precision and durability in the cutting and grinding industry. With their unrivaled strength and longevity, these tools have become essential for a wide range of applications, from construction and manufacturing to gemstone processing and even medical procedures. Although the brilliance of diamond wheels has been recognized for decades, recent advancements have taken their capabilities to new heights, making them an even more attractive investment for businesses seeking efficiency, cost-effectiveness, and environmental sustainability. In this article, we will delve into the economic and environmental advantages that diamond wheels offer and how they can transform industries.

From start to finish, the production of diamond wheels involves a careful and meticulous process. Each wheel is composed of a steel core, onto which diamond grit is firmly bonded. This unique construction gives diamond wheels their exceptional strength and allows them to cut through even the hardest materials with ease. Furthermore, the development of advanced manufacturing techniques has enabled diamond wheels to be produced in various shapes and sizes, catering to the specific needs of different industries.

When it comes to economic advantages, diamond wheels undoubtedly excel in multiple areas. Firstly, their longevity is unparalleled. These wheels have the ability to outlast many other cutting and grinding tools, such as abrasive wheels or traditional grinding stones, making them a cost-effective investment for businesses. Not only do they reduce the frequency of tool replacements, but they also minimize downtime, increasing productivity and profitability.

Moreover, the high precision offered by diamond wheels translates into better quality finishes and fewer errors. With their exceptional control and accuracy, these wheels allow for intricate detailing and smooth, clean cuts. The reduced need for rework not only enhances the overall efficiency of operations but also saves both time and resources for businesses. Additionally, the versatility of diamond wheels, combined with their unparalleled cutting capabilities, reduces the need for multiple tools, further streamlining processes and reducing costs.

Furthermore, the environmental advantages of diamond wheels cannot be overstated. In an era where sustainability is at the forefront of many businesses' priorities, diamond wheels offer a compelling solution. Unlike abrasive wheels, diamond wheels do not generate harmful dust particles or release toxic fumes during operation. This not only safeguards the health and well-being of operators but also contributes to a cleaner and safer working environment.

Additionally, the long lifespan of diamond wheels significantly reduces waste generation. Traditional grinding stones and abrasive wheels often wear out quickly and require frequent replacements, resulting in a substantial volume of discarded tools. Conversely, diamond wheels can last up to 100 times longer, drastically reducing the number of disposed units and the associated environmental impact. This sustainable approach not only aligns with growing societal expectations but also positions businesses as responsible stewards of the planet.

For Johnson Tools, a leading manufacturer of diamond wheels, these advancements represent an incredible opportunity to reshape the industry. With our commitment to innovation and craftsmanship, we strive to deliver superior tooling solutions that revolutionize efficiency and sustainability for businesses worldwide. Our diamond wheels are meticulously crafted to embody the perfect blend of durability, precision, and environmental consciousness, ensuring that your investment in brilliance is one that pays dividends for years to come.

In conclusion, the economic and environmental advantages of diamond wheels make them an indispensable tool for businesses across various industries. Their longevity, precision, and versatility not only optimize efficiency, reduce costs, and improve overall output quality but also minimize waste generation and environmental impact. With advancements in manufacturing techniques continuing to push the boundaries of what diamond wheels can achieve, investing in brilliance has never been more rewarding. Choose Johnson Tools, and unveil the brilliant advancements of diamond wheels for your business today.

Conclusion

From the economic standpoint, the brilliant advancements of diamond wheels have truly revolutionized various industries, ranging from construction to manufacturing. With their unparalleled efficiency and durability, these cutting-edge tools have not only enhanced productivity but also reduced downtime and maintenance costs significantly. By maximizing material removal rates and extending tool life, diamond wheels have become an indispensable asset for businesses looking to stay ahead of the competition.

Moreover, from an environmental perspective, the adoption of diamond wheels has contributed to a greener and more sustainable future. With their ability to cut through hard materials effortlessly and with minimal friction, these wheels generate less heat and reduce energy consumption, thereby minimizing carbon emissions. Additionally, the long lifespan and recyclability of diamond wheels further minimize waste production. It is indisputable that by embracing these brilliant advancements, industries are taking a step towards a more eco-friendly approach to manufacturing and construction.

Furthermore, the safety aspect cannot be overlooked when discussing the wonders of diamond wheels. The exceptional hardness and strength of diamonds provide superior stability during cutting operations, reducing the risk of accidents or injuries. This aspect is particularly crucial in high-risk industries where workers' safety is of utmost priority. By utilizing diamond wheels, companies are not only enhancing productivity but also safeguarding their workforce, ensuring a safe and secure working environment.

In conclusion, the brilliant advancements of diamond wheels have revolutionized industries, bringing forth dazzling efficiency. From the economic benefits of increased productivity and reduced maintenance costs to the environmental advantages of energy efficiency and waste reduction, these cutting-edge tools have undoubtedly made a lasting impact. Moreover, the enhanced safety provided by diamond wheels further emphasizes their irreplaceable role in various high-risk industries. As we look towards the future, it is evident that diamond wheels will continue to shine brightly, propelling industries towards unprecedented achievements and a brighter, more sustainable tomorrow.