Global Leading Diamond Tool Manufacturer.

Unleashing Diamond's Brilliance: A Guide To Wet Diamond Polishing Pads

Welcome to our comprehensive guide on wet diamond polishing pads, where we unlock the secrets behind unleashing a diamond's brilliance. If you've ever wondered how professionals achieve flawless and dazzling finishes on various surfaces, this article is your key to uncovering the art of wet diamond polishing. From intricately designed countertops to pristine marble floors, we invite you to delve deeper into the world of diamond polishing pads and explore the techniques that bring out the true radiance of these precious stones. Whether you're a DIY enthusiast, a contractor, or simply a curious reader, join us as we navigate through the tips, tricks, and expert insights that will empower you to achieve flawless results and make your surfaces shine like never before. Let us embark on this journey together and witness the transformative power of wet diamond polishing pads.

- Understanding the Importance of Wet Diamond Polishing Pads

Understanding the Importance of Wet Diamond Polishing Pads

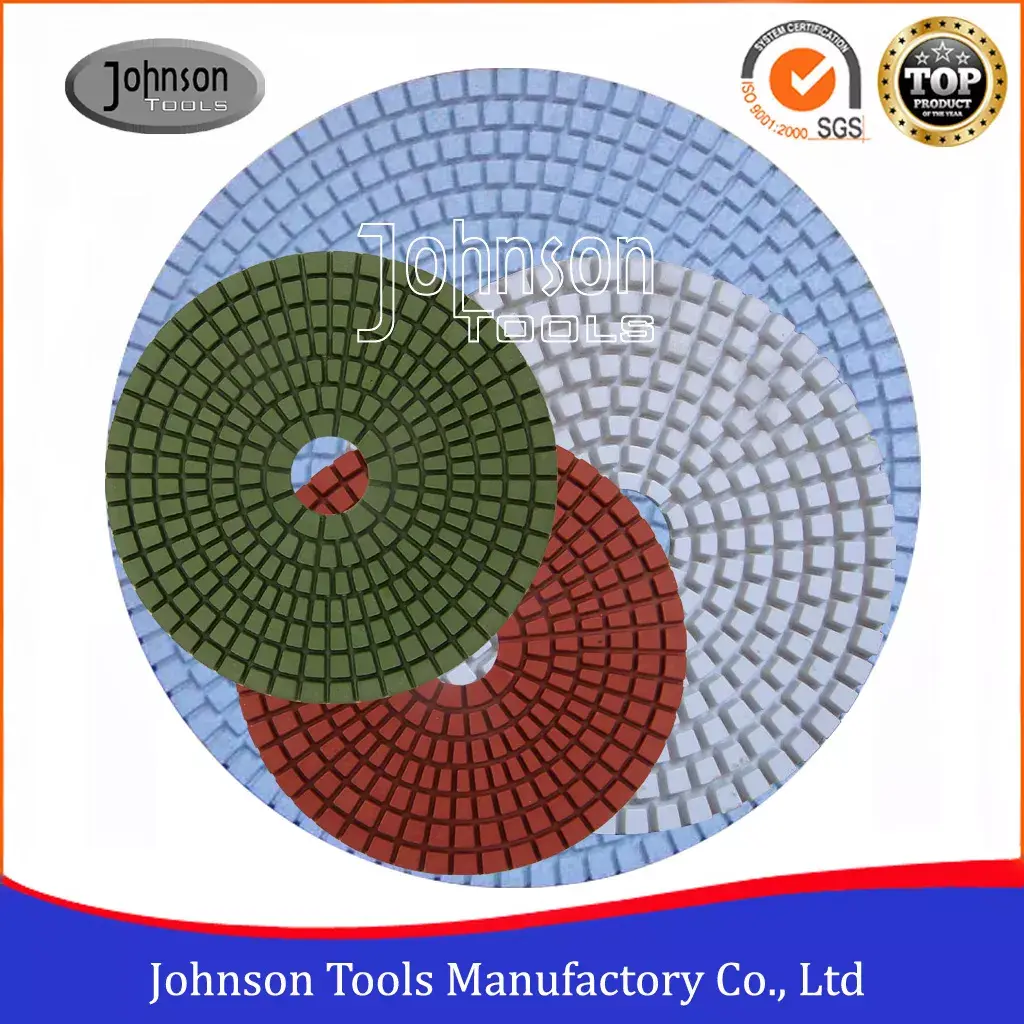

When it comes to achieving the perfect finish on your diamond surfaces, wet diamond polishing pads are an essential tool to have in your arsenal. These pads, specifically designed for use with water, offer numerous benefits that make them indispensable for achieving stunning results. In this comprehensive guide, we will explore the importance of wet diamond polishing pads, highlighting their advantages and why they are the preferred choice for professionals and enthusiasts alike.

Wet diamond polishing pads, as the name suggests, are designed to be used with water during the polishing process. This water-cooled method offers distinct advantages over dry polishing methods, enhancing the overall efficiency and effectiveness of the polishing task. By providing a continuous flow of water, these pads prevent the build-up of heat, reducing the risk of damage to the diamond surface and extending the lifespan of the pad itself.

Johnson Tools, a renowned brand in the diamond tool industry, understands the significance of wet diamond polishing pads and has developed a range of high-quality pads that deliver exceptional results. With their commitment to innovation and customer satisfaction, Johnson Tools has become a trusted name among professionals and enthusiasts seeking top-notch diamond polishing pads.

One of the key advantages of wet diamond polishing pads is their ability to produce a superior finish. The continuous flow of water not only helps to cool the diamond surface but also assists in removing debris and residue that may accumulate during the polishing process. This ensures a clean and clear surface, free from scratches and imperfections, resulting in a highly reflective and brilliant shine.

Another significant benefit of wet diamond polishing pads is their versatility. These pads can be used on a wide range of materials, including granite, marble, concrete, and other stone surfaces. This versatility makes them a must-have tool for professionals in the construction and renovation industry, as well as for DIY enthusiasts looking to enhance the appearance of their home.

In addition to their superior finish and versatility, wet diamond polishing pads also offer improved safety during the polishing process. The water-cooled method helps to minimize the release of hazardous dust particles, protecting the health of the user and improving the overall air quality of the working environment. This makes wet diamond polishing pads a safer option compared to dry polishing methods that can generate harmful dust particles.

Not only do wet diamond polishing pads offer outstanding performance, but they also contribute to sustainability and cost-effectiveness. The water used during the polishing process helps to contain dust particles, minimizing the need for extensive clean-ups. Additionally, the extended lifespan of the wet diamond polishing pads means fewer replacements are required, reducing waste and ultimately saving you money in the long run.

When using wet diamond polishing pads, it is important to follow the recommended guidelines for optimal results. Johnson Tools provides comprehensive instructions on the proper use and maintenance of their wet diamond polishing pads to maximize their performance and longevity. By following these guidelines, you can ensure that your diamond surfaces consistently achieve the brilliance they deserve.

In conclusion, wet diamond polishing pads are a crucial tool for anyone seeking to unlock the true potential of their diamond surfaces. With their ability to produce a superior finish, versatility, safety benefits, and contribution to sustainability, wet diamond polishing pads have earned their place as the preferred choice among professionals and DIY enthusiasts. Trust Johnson Tools to provide you with top-of-the-line wet diamond polishing pads that will transform your surfaces into dazzling works of art.

- Choosing the Right Wet Diamond Polishing Pad for Your Project

Choosing the Right Wet Diamond Polishing Pad for Your Project

When it comes to achieving the perfect finish on your stone surfaces, wet diamond polishing pads are an essential tool in any craftsman's arsenal. These pads have revolutionized the industry, offering superior results and unparalleled shine. However, with so many options available on the market, selecting the right wet diamond polishing pad for your project can be a daunting task. In this guide, we will delve into the world of wet diamond polishing pads, focusing on how to choose the perfect pad for your specific needs.

At Johnson Tools, we understand the importance of quality and precision in your work. That's why we have developed a comprehensive range of wet diamond polishing pads to cater to every project requirement. By understanding the intricacies of these pads, you can make an informed decision and achieve stunning results.

Different Types of Wet Diamond Polishing Pads

Before diving into the selection process, it's crucial to understand the different types of wet diamond polishing pads available. Each type offers unique characteristics and benefits, catering to different stone surfaces and finishes.

1. Electroplated Pads: These pads are embedded with diamond particles electroplated onto their surface. They are ideal for polishing hard materials such as granite and engineered stone. Electroplated pads are known for their aggressive cutting action and are particularly useful for removing scratches or leveling uneven surfaces.

2. Resin Bond Pads: Resin bond pads are known for their versatility and are widely used in the stone and concrete polishing industry. These pads offer excellent durability and are suitable for a variety of stones, including marble, limestone, and terrazzo. They provide a high gloss finish and are available in various grits to cater to different stages of polishing.

3. Flexible Pads: As the name suggests, flexible pads have a softer construction, allowing for more flexibility and adaptability. These pads are often used for curved or contoured surfaces, providing a consistent and smooth finish. They are mainly employed in the final polishing stages to achieve a mirror-like sheen on stones like marble and travertine.

Choosing the Right Wet Diamond Polishing Pad

Now that we have acquainted ourselves with the different types of wet diamond polishing pads let's delve into the process of selecting the right pad for your project.

1. Determine the Material: The type of material you are working with will dictate the choice of pad. For granite or other hard stones, electroplated pads are the ideal choice. For softer stones like marble or travertine, resin bond or flexible pads are more suitable.

2. Consider Grit Size: Wet diamond polishing pads are available in various grit sizes, ranging from coarse to fine. Coarser grits are used for initial stages of grinding and removing imperfections, while finer grits are employed for final polishing. It's crucial to consider the specific requirements of your project to select the appropriate grit size.

3. Assess Pad Durability: Depending on the extent of your project, the durability of the wet diamond polishing pad is crucial. Resin bond and flexible pads are known for their longevity, making them a popular choice for larger projects.

4. Wet or Dry Usage: While the focus of this guide is on wet diamond polishing pads, it's worth mentioning the option of dry usage. Some pads can be used both wet and dry, providing flexibility in application. However, for optimal results and longevity, it is generally recommended to use wet diamond polishing pads with water.

Selecting the right wet diamond polishing pad is a crucial step in achieving the desired finish for your stone surfaces. With the comprehensive range of wet diamond polishing pads offered by Johnson Tools, you can trust in the performance and quality of our products. Consider the material, grit size, durability, and wet or dry usage when selecting your pads, and unleash the brilliance of diamonds on your projects with Johnson Tools.

- Step-by-Step Guide to Properly Using Wet Diamond Polishing Pads

Unleashing Diamond's Brilliance: A Step-by-Step Guide to Properly Using Wet Diamond Polishing Pads

Diamond polishing is an essential technique that can transform the look and feel of various surfaces, such as tiles, concrete, and natural stone. To achieve the desired brilliant finish, the use of high-quality wet diamond polishing pads is crucial. In this comprehensive guide, we will walk you through the step-by-step process of effectively utilizing wet diamond polishing pads. Whether you are a DIY enthusiast or a professional contractor, this guide will ensure that you unleash the true brilliance of diamonds in your projects.

Step 1: Selecting the Right Wet Diamond Polishing Pads

To begin, it is vital to choose the appropriate wet diamond polishing pads for your specific application. Johnson Tools, a trusted brand in the industry, offers a wide range of wet diamond polishing pads, suitable for a variety of surfaces and grit levels. Each pad is designed to provide optimal results in terms of polishing efficiency and durability.

Step 2: Preparing the Surface

Before you begin the polishing process, it is important to prepare the surface that you will be working on. Ensure that the surface is clean, free from any debris or loose particles. Depending on the material, you may need to use a cleaning solution or specialized cleaner to remove any stubborn stains or residue. Take the necessary precautions to protect surrounding areas from splashes or overspray.

Step 3: Wetting the Diamond Polishing Pad

Wet diamond polishing pads require constant lubrication during the polishing process to prevent overheating and ensure smooth operation. Begin by wetting the surface and the polishing pad with water. Use a spray bottle or a water source to maintain a consistent flow of water throughout the process. This will not only enhance the pad's lifespan but also increase its effectiveness in polishing.

Step 4: Attaching the Pad to a Polisher

Securely attach the wet diamond polishing pad to a compatible polisher, ensuring that it is centered and firmly fixed. Johnson Tools provides a range of adaptable Velcro-backed wet diamond polishing pads that easily adhere to most polishers, ensuring stability and precision during the polishing process.

Step 5: Starting the Polishing Process

With the pad securely attached to the polisher, it is time to initiate the polishing process. Begin at a slow speed, gradually increasing the velocity as you gain control and confidence. Apply light pressure on the surface, making even and overlapping passes to ensure consistent polishing results. Remember to keep the pad and surface wet throughout the process, as this aids in cooling the pad and achieving a smooth finish.

Step 6: Adjusting the Grit Level

Depending on the surface and the desired outcome, it may be necessary to adjust the grit level of the wet diamond polishing pad during the process. Beginning with a lower grit pad facilitates the initial removal of imperfections, such as scratches or uneven surfaces. As you progress, gradually increase the grit level to achieve a finer and more polished finish. Johnson Tools offers a variety of grit options, allowing you to customize the polishing process to your specific requirements.

Step 7: Finishing Touches

Once you have achieved the desired level of polish, it is time for the finishing touches. Thoroughly clean the surface to remove any residual polishing compounds, using a clean cloth or mop. Inspect the surface for any imperfections and repeat the process if necessary, using a higher grit pad for additional refinement. Finally, allow the surface to dry and marvel at the brilliance that wet diamond polishing pads have brought to your project.

With the step-by-step guide provided above, you are now equipped with the knowledge and techniques needed to properly use wet diamond polishing pads. Johnson Tools, with its range of superior wet diamond polishing pads, ensures that you can achieve professional-level results in your projects. Remember to prioritize safety, adhere to manufacturer guidelines, and enjoy the spectacular brilliance that wet diamond polishing pads can bring to various surfaces.

- Tips and Tricks for Maximizing Diamond's Brilliance Through Wet Polishing

When it comes to achieving the utmost brilliance in diamonds, using wet diamond polishing pads is a technique that can significantly enhance the overall appearance and sparkle of these precious gemstones. In this comprehensive guide, we will explore the benefits of wet diamond polishing pads and provide you with tips and tricks to maximize their effectiveness. As an industry leader in diamond tools, Johnson Tools is dedicated to helping you unleash the full potential of your diamonds.

1. What are Wet Diamond Polishing Pads?

Wet diamond polishing pads are advanced tools specifically designed to refine the surface of diamonds and enhance their brilliance. Unlike dry polishing methods, which generate heat and friction, wet polishing utilizes water as a coolant, preventing damage to the diamond and maintaining a consistent level of performance throughout the process. These pads are typically made with high-quality diamond particles bonded to a flexible backing, allowing for seamless and controlled polishing.

2. The Advantages of Wet Diamond Polishing Pads:

2.1 Superior Cooling: The primary advantage of wet diamond polishing pads is their superior cooling capacity. By continuously wetting the surface, heat generated during the polishing process is dissipated, reducing the risk of thermal damage to the diamond. This results in a longer lifespan for the diamond and ensures consistent brilliance.

2.2 Enhanced Polishing: Wet polishing pads provide a smoother polishing experience, allowing for greater control over the polishing action. By reducing the friction between the diamond and the polishing pad, wet polishing helps to achieve a higher level of precision, resulting in a more refined and lustrous surface.

2.3 Dust Reduction: Wet diamond polishing pads significantly reduce the amount of dust produced during the polishing process. The water acts as a binder, preventing loose particles from becoming airborne and minimizing the risk of inhalation. This not only creates a healthier working environment but also facilitates easier cleanup.

3. Tips and Tricks for Maximizing Diamond's Brilliance:

3.1 Pre-Polishing Preparation: Before starting the wet diamond polishing process, it is essential to ensure that the diamond is clean and free from any impurities or residues. Use a soft brush and mild detergent to gently clean the diamond, and rinse thoroughly with water. Inspect the diamond under a light source to ensure it is completely clean before proceeding with wet polishing.

3.2 Selecting the Right Grit: Wet diamond polishing pads are available in various grits, ranging from coarse to fine. When starting, begin with a coarser grit to remove any scratches or imperfections on the diamond's surface. Gradually progress to finer grits to achieve a smoother and more reflective finish. It is recommended to use a sequence of grits, starting from around 100 and moving up to 3000 or higher for a flawless, mirror-like appearance.

3.3 Proper Technique: To maximize the effectiveness of wet diamond polishing pads, it is crucial to apply consistent pressure and maintain a steady motion throughout the polishing process. Use circular or figure-eight motions to evenly distribute the polishing action. Remember to keep the pad moist by applying water regularly during polishing and frequently clean the pad to remove any accumulated debris.

3.4 Finishing Touches: After completing the wet polishing process, use a soft, lint-free cloth to gently dry the diamond. Inspect the diamond under different lighting conditions to evaluate the level of brilliance achieved. If necessary, repeat the polishing process with finer grits to achieve the desired result. Finally, add additional sparkle to the diamond by applying a specially formulated diamond polish solution.

Wet diamond polishing pads are indispensable tools for maximizing the brilliance and overall beauty of diamonds. By utilizing the cooling properties of water and employing the right techniques, these pads can transform a dull and lackluster diamond into a dazzling masterpiece. Johnston Tools is proud to present this comprehensive guide, offering valuable tips and tricks to unleash the full potential of your diamonds. Elevate your diamond polishing experience and unlock its true brilliance with wet diamond polishing pads.

- Maintaining and Caring for Wet Diamond Polishing Pads for Longevity

Unleashing Diamond's Brilliance: A Guide to Maintaining and Caring for Wet Diamond Polishing Pads for Longevity

In the world of polishing and refining, wet diamond polishing pads have become an essential tool for achieving the desired brilliance and shine on various surfaces. These pads, when used with precision and care, can transform even the dullest materials into stunning pieces of art. However, to ensure their longevity and optimum performance, it is crucial to understand how to properly maintain and care for these wet diamond polishing pads. In this comprehensive guide, we will delve into the intricacies of maintaining and caring for these valuable tools.

1. The Importance of Wet Diamond Polishing Pads:

Wet diamond polishing pads are specially designed to enhance the polishing process by utilizing water as a lubricant. This technique not only adds a cooling effect but also flushes away debris generated during polishing, extending the pad's lifespan. Additionally, the water enhances the polishing efficiency, resulting in a superior level of clarity, shine, and brilliance.

2. Proper Cleaning and Storage Techniques:

Cleaning wet diamond polishing pads after each use is crucial for maintaining their effectiveness and longevity. Start by rinsing the pads with clean water to remove any surface-level debris and residues. Gently scrub the pads with a soft brush or cloth using mild detergent to eliminate any stubborn stains or build-up. Rinse thoroughly and allow them to air dry.

Proper storage is equally essential. After cleaning, ensure the pads are completely dry before storing them in a cool and dry environment. It is advisable to stack the pads vertically, rather than horizontally, to prevent deformations and preserve their shape.

3. Regular Inspection and Replacement:

Regular inspection of the wet diamond polishing pads is vital to identify any signs of wear and tear. Constant use can lead to the gradual wearing down of the diamond grit, resulting in reduced performance. Examine the pads closely for any cracks, uneven surfaces, or loss of bonding between the diamond particles and the pad material. If any such issues are detected, it is recommended to replace the pads immediately to avoid compromising the quality of your work.

4. Choosing the Right Pad for Specific Applications:

Every polishing project demands a specific type of wet diamond polishing pad. It is essential to select the appropriate pad grit for the material being polished. Coarse pads are suitable for initial grinding and removing deep scratches, while finer grits are ideal for achieving a smooth and highly polished finish. Using the wrong pad can result in subpar results or even damage to the material.

As experts in the field, Johnson Tools offers a wide range of wet diamond polishing pads suitable for various applications. Our pads are designed to deliver exceptional performance, durability, and longevity, ensuring that your polishing projects are executed to perfection.

Proper care and maintenance of wet diamond polishing pads are essential for preserving their brilliance and longevity. By following the guidelines outlined in this comprehensive guide, you can extend the lifespan of your pads and ensure consistently outstanding results. Choose wisely, rely on quality products such as Johnson Tools' wet diamond polishing pads, and unleash the full potential of your polishing projects. Remember, the key lies in meticulously maintaining and caring for these valuable tools.

Conclusion

In conclusion, wet diamond polishing pads have truly revolutionized the art of diamond polishing. By harnessing the power of water, these pads unlock the full brilliance and beauty of diamonds, allowing them to shine at their utmost potential. Whether you are a professional jeweler or a passionate DIY enthusiast, incorporating wet diamond polishing pads into your polishing routine is essential. Not only do these pads ensure a smooth and flawless finish, but they also increase the longevity of your diamond tools and enhance the overall polishing experience. So, don't miss out on the opportunity to unleash the brilliance of your diamonds – make the switch to wet diamond polishing pads today and witness the extraordinary transformation firsthand.