Global Leading Diamond Tool Manufacturer.

Unveiling The Versatility Of Oscillating Tool Saw Blades: A Cutting-edge Guide

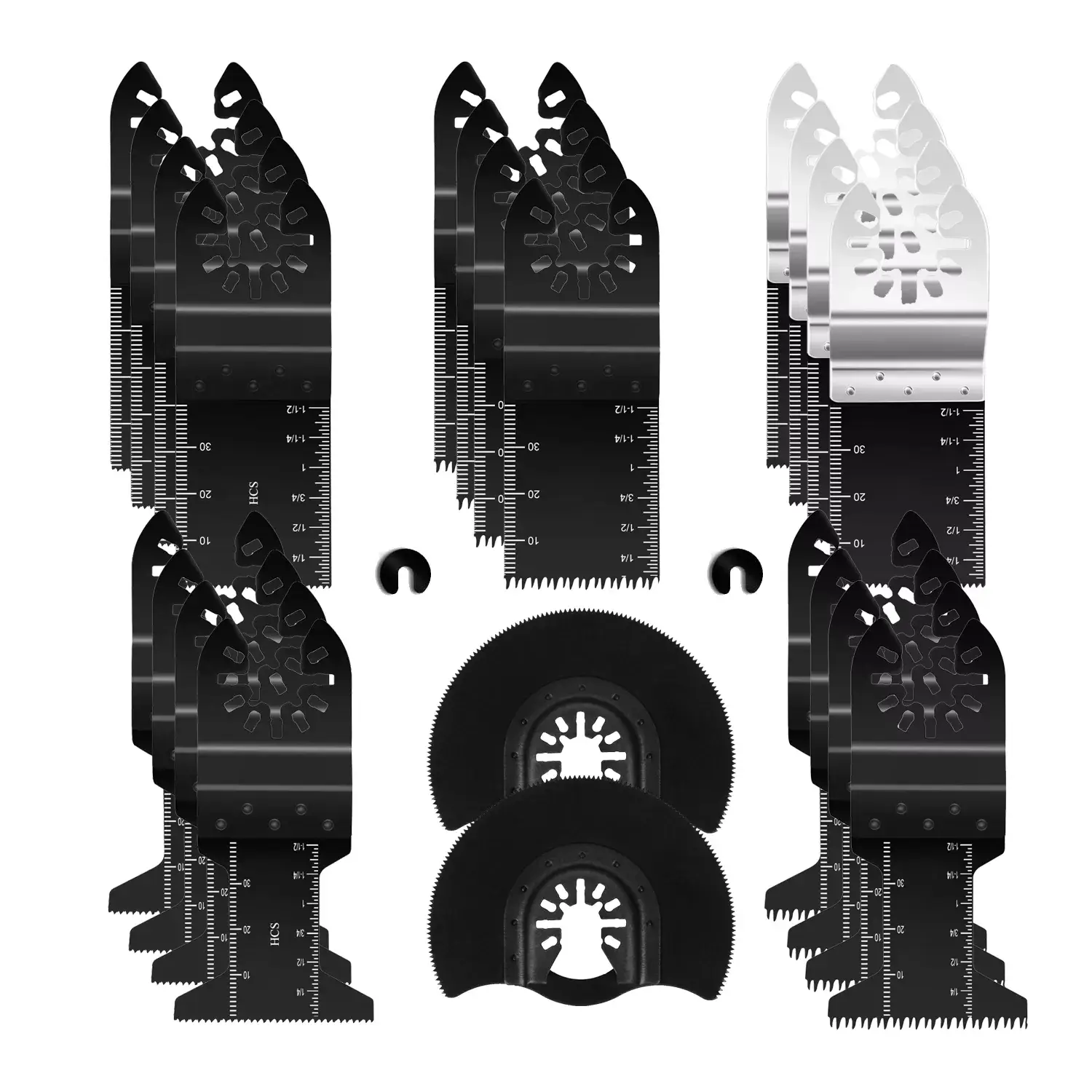

Welcome to our cutting-edge guide on unveiling the versatility of oscillating tool saw blades. If you're fascinated by the world of power tools and want to discover the endless possibilities of these essential accessories, this article is a must-read. We will delve into the realm of oscillating tool saw blades, exploring their incredible versatility and the multitude of tasks they can accomplish. Whether you're a DIY enthusiast, a professional contractor, or someone looking to expand their tool collection, join us as we take you on a journey to unlock the true potential of these remarkable tools. Prepare to be amazed by the myriad of applications, from precise cuts and flush trimming to scraping and sanding. Grab your toolkit, and let's embark on a captivating exploration of oscillating tool saw blades like never before.

Understanding the Basics: What is an Oscillating Tool Saw Blade?

In the realm of DIY projects and professional construction work, having the right tools for the job is essential. One tool that has gained significant popularity in recent years is the oscillating tool saw blade. Designed for versatility and precision, these blades have revolutionized the way we approach cutting tasks. In this comprehensive guide, we will delve into the world of oscillating tool saw blades, uncovering their versatility and exploring their numerous applications.

At Johnson Tools, we take immense pride in providing high-quality oscillating tool saw blades that exceed expectations. Our commitment to excellence and customer satisfaction drives us to create innovative tools that make cutting tasks easier, more efficient, and ultimately, more enjoyable.

So, what exactly is an oscillating tool saw blade? An oscillating tool saw blade is a specially designed cutting accessory that attaches to an oscillating multi-tool. These blades are known for their unique oscillating motion, which sets them apart from traditional saws. Instead of a circular or reciprocating motion, oscillating tool saw blades move back and forth at a rapid pace, allowing for precise and controlled cuts.

The versatility of oscillating tool saw blades is unparalleled. With the ability to cut through a wide range of materials, from wood and metal to plastic and drywall, these blades are a must-have addition to any toolbox. Their adaptability makes them the go-to choice for both professionals and DIY enthusiasts alike.

When selecting an oscillating tool saw blade, it is important to consider the specific requirements of your project. Different blades are designed for different purposes, and finding the right one for the job is crucial. The tooth pattern, blade width, and material composition all play a role in determining the blade's effectiveness for a particular task.

For instance, if you are working on a flooring project and need to make precise cuts around corners or in tight spaces, a narrow blade with a fine-tooth pattern would be an ideal choice. On the other hand, if you are cutting through thick metal pipes, a wider blade with a more aggressive tooth pattern would provide the necessary cutting power.

One of the primary advantages of oscillating tool saw blades is their ability to make plunge cuts. Unlike traditional saws, which require a starting point, oscillating tool saw blades can be plunged directly into the material, making it easier to create cutouts and access hard-to-reach areas. This unique feature makes these blades highly efficient and eliminates the need for additional tools or manual cutting techniques.

Another notable benefit of oscillating tool saw blades is their ability to remove grout. With the right blade attachment, these versatile tools can be used to remove old or damaged grout between tiles, allowing for seamless repairs or renovations. This is particularly useful in bathroom or kitchen projects, where grout maintenance is often required.

In conclusion, oscillating tool saw blades are a game-changer in the world of cutting tools. Their versatility, precision, and efficiency make them a valuable addition to any toolbox. At Johnson Tools, we are passionate about providing high-quality oscillating tool saw blades that meet the demands of our customers. Our dedication to excellence and commitment to innovation have earned us a reputation as a trusted brand in the industry. So, whether you are a professional contractor or a DIY enthusiast, consider adding an oscillating tool saw blade from Johnson Tools to your collection and experience the difference firsthand.

Exploring Different Blade Types: From Wood to Metal, Which Blade for Which Material?

Unveiling the Versatility of Oscillating Tool Saw Blades: A Cutting-edge Guide"

In the realm of DIY and professional construction projects, the oscillating tool has become an indispensable asset. And at the heart of this versatile machine lies its saw blades, which determine the tool's cutting capabilities. In this article, we delve into the realm of oscillating tool saw blades, exploring their different types and their suitability for various materials. So whether you're working with wood or metal, we've got you covered with the ultimate guide to choosing the right blade for the right material.

Wood Blades:

When it comes to cutting through wood, the type of oscillating tool saw blade you choose can significantly impact the outcome of your project. For general woodcutting tasks, the standard wood blade with its coarse teeth serves as a reliable option. They offer a combination of speed and precision, making them ideal for tasks such as trimming door jambs or creating clean, straight cuts on wooden planks.

For more intricate woodwork, such as intricate designs or fine detailing, a specialized fine-tooth wood blade is recommended. These blades have smaller teeth, allowing for more delicate and precise cuts. Whether you're working on a DIY craft project or installing intricate molding, the fine-tooth wood blade will be your go-to choice.

Metal Blades:

When it comes to tackling metal, utilizing the right blade is crucial for achieving clean and accurate cuts. Unlike wood, metal requires a tougher and more durable blade to withstand the high heat generated during the cutting process. Bi-metal blades are the preferred choice for cutting through various types of metal, including steel, copper, and aluminum. These blades are constructed with a combination of high-speed steel and a flexible alloy backing. This construction not only enhances the blade's strength but also increases its lifespan, making it a cost-effective option.

In instances where you encounter more robust metals, such as nails or screws, a carbide-grit blade should be your tool of choice. These blades feature a grit-coated edge that effortlessly grinds through stubborn metals, allowing you to work efficiently without worrying about blade wear or reduced cutting performance.

Multi-material Blades:

For those working on projects that involve a combination of materials, investing in a multi-material blade is a wise choice. These blades are designed to seamlessly cut through different types of materials, including wood, metal, plastic, and even drywall. With their universal tooth pattern and unique blade geometry, multi-material blades offer versatility and enable smooth, precise cuts across various surfaces. Whether you're performing renovations or tackling construction projects, the multi-material blade is an invaluable addition to your oscillating tool's arsenal.

In conclusion, the versatility of oscillating tool saw blades cannot be overstated. When armed with the right blade, your oscillating tool becomes a reliable companion for various cutting tasks. From standard wood blades for basic woodcutting to specialized blades for metalwork and multi-material blades for diverse projects, Johnson Tools offers a comprehensive range of high-quality, durable, and efficient blades to suit every need. So, next time you embark on a DIY adventure or undertake a professional construction project, remember to choose the right oscillating tool saw blade from Johnson Tools, your trusted partner in precision cutting.

Mastering Precision Cuts: Techniques for Making Straight and Curved Cuts with Oscillating Saw Blades.

When it comes to precision cuts, the indispensable tool that every DIY enthusiast or professional carpenter should have in their arsenal is an oscillating tool with saw blades. These versatile tools, also known as multi-tools, have revolutionized the way cuts are made, offering a level of precision and control that is unmatched by traditional cutting tools. In this comprehensive guide, we will explore the techniques for making straight and curved cuts with oscillating saw blades, and how Johnson Tools, the leading brand in the industry, has mastered the art of precision cuts.

Mastering Precision Cuts:

Oscillating tool saw blades are designed to tackle a wide range of cutting tasks, making them the perfect tool for any project. Whether you need to make straight cuts or intricate curved cuts, these blades offer the precision and control necessary to achieve professional-grade results.

1. Straight Cuts:

To master straight cuts with oscillating saw blades, it is essential to follow a few key techniques. Firstly, ensure that the blade is securely fastened to the tool, as any loose fitting can result in imprecise cuts. Secondly, select the appropriate blade for the material you are cutting. Johnson Tools offers a diverse range of blades specifically designed for different materials, such as wood, metal, and plastic. Lastly, maintain steady pressure while cutting, allowing the blade to glide smoothly through the material. By following these techniques, you can easily achieve straight cuts with precision and accuracy.

2. Curved Cuts:

Curved cuts require a slightly different approach. To achieve seamless curved cuts, start by selecting a saw blade with a narrow width, as this allows for greater maneuverability. Next, mark the desired curve on the material and carefully guide the oscillating tool along the marked line, maintaining a steady and controlled motion. Johnson Tools' oscillating saw blades provide the flexibility and agility needed to effortlessly navigate around tight curves, ensuring flawless results every time.

Why Choose Johnson Tools:

When it comes to oscillating tool saw blades, Johnson Tools stands out as the industry leader. With years of expertise and an unwavering commitment to quality, Johnson Tools has mastered the art of precision cutting.

1. Exceptional Durability:

Johnson Tools' saw blades are crafted from high-quality materials, ensuring their durability and longevity. Whether you are cutting through tough hardwood or delicate plastic, these blades can withstand the rigors of any cutting task, providing consistent performance for years to come.

2. Versatility:

Johnson Tools offers a diverse range of oscillating saw blades tailored for various materials and cutting purposes. From the finest tooth blades for intricate cuts to aggressive blades for rapid material removal, Johnson Tools has the perfect blade to suit your needs, making them the go-to choice for both professionals and DIY enthusiasts alike.

3. Precision and Control:

The hallmark of Johnson Tools' oscillating saw blades is their unrivaled precision and control. With their ultra-sharp teeth and optimized blade designs, these blades ensure smooth and accurate cuts every time. Whether it's a straight cut or a complex curved cut, Johnson Tools' blades provide the necessary precision to achieve flawless results.

In conclusion, mastering precision cuts with oscillating tool saw blades is made possible by the techniques and expertise offered by Johnson Tools. With their exceptional durability, versatility, and unwavering commitment to precision, Johnson Tools has truly unlocked the full potential of oscillating saw blades. So, whether you are a professional seeking the best tools for your craft or a DIY enthusiast looking to tackle home improvement projects, Johnson Tools is your trusted partner in achieving precision and excellence.

Empowering DIY enthusiasts: How to Choose the Right Blade for Home Renovation Projects.

DIY enthusiasts know the thrill of taking on home renovation projects and experiencing the satisfaction of transforming their living spaces. In these endeavors, having the right tools is paramount, and one such indispensable tool is the oscillating tool. With its precision and versatility, an oscillating tool can tackle a wide range of tasks, from cutting through materials to sanding and scraping. And what plays a pivotal role in enhancing the performance of this tool is the choice of the oscillating tool saw blade.

At Johnson Tools, we understand the importance of selecting the correct blade for your oscillating tool. In this cutting-edge guide, we aim to empower DIY enthusiasts by providing comprehensive insights into the various types of oscillating tool saw blades and their applications. With the knowledge gained from this guide, you'll be well-equipped to make informed decisions and effortlessly achieve professional results in your home renovation projects.

1. Understanding the Oscillating Tool Saw Blade:

The oscillating tool saw blade is a crucial component that determines the tool's cutting capabilities. These blades are specially designed to oscillate or move side to side rapidly, enabling precise and controlled cutting. They are available in various designs and thicknesses, each catering to specific tasks and materials.

2. Different Types of Oscillating Tool Saw Blades:

a. Bi-Metal Blades: These blades, featuring a combination of high-speed steel and heat-treated steel, offer enhanced durability and flexibility. Ideal for cutting through wood, metal, nails, and plastic, they are perfect for versatile projects where you need a blade that can withstand demanding tasks.

b. Diamond Blades: If you're working on tougher materials like tiles, ceramics, or concrete, a diamond blade is your best choice. With its diamond-coated edge, this blade effortlessly cuts through hard surfaces, making it an essential tool for renovating bathrooms, kitchen floors, or even outdoor spaces.

c. Carbide Blades: Carbide blades are designed for heavy-duty applications, particularly when tackling hardwood, plaster, drywall, or cement. With their sharp teeth and durable construction, these blades ensure precise and efficient cutting, even in demanding renovation projects.

d. Scraper Blades: For removing old paint, adhesive, or caulk, scraper blades are essential. These blades feature a flat, wide edge capable of scraping effectively without damaging the underlying surface.

e. Flush-Cutting Blades: Designed with a unique curved shape, flush-cutting blades are ideal for cutting materials in tight or difficult-to-reach areas. Whether you need to trim baseboards, door jambs, or pipes, these blades provide clean and close cuts without causing any damage.

3. Choosing the Right Blade for Your Project:

When selecting an oscillating tool saw blade, it's vital to consider the material you'll be working with, the desired cutting depth, and the type of cut required. Assessing these factors will help you make an informed decision:

a. Material: Different blades are designed for specific materials. Ensure your chosen blade is suitable for the material you intend to cut or remove.

b. Cutting Depth: Consider the thickness or depth you need to cut through. Some blades offer adjustable cutting depths, while others are specifically designed for shallow or deep cuts.

c. Type of Cut: Understand the type of cut you need to make, whether it's straight cuts, curved cuts, plunge cuts, or flush cuts. Choose a blade that matches your desired cutting style.

With this comprehensive guide, we have unveiled the versatility of oscillating tool saw blades and empowered DIY enthusiasts to choose the right blade for their home renovation projects. Remember, investing in high-quality blades from Johnson Tools enhances your tool's performance and ensures professional results. So, whether you're an experienced DIY enthusiast or just starting your home improvement journey, selecting the correct oscillating tool saw blade will undoubtedly elevate your woodworking or remodeling projects to new heights of excellence.

Unleashing the Potential: Innovative Uses of Oscillating Tool Saw Blades Beyond Cutting.

Johnson Tools is proud to present the ultimate guide to the versatility of oscillating tool saw blades. While these blades are primarily known for their cutting capabilities, their potential extends far beyond traditional uses. In this article, we will explore the innovative and unconventional applications of oscillating tool saw blades, demonstrating how they can unlock new levels of efficiency and creativity in various industries.

1. Sanding and Shaping Surfaces:

One of the many remarkable qualities of oscillating tool saw blades is their ability to perform precision sanding and shaping tasks. By attaching a sanding pad or carbide rasp to the blade, craftsmen and DIY enthusiasts can effortlessly smoothen rough surfaces, prep materials for painting, or tackle intricate shaping projects. The oscillating motion of the blade ensures consistent and controlled sanding even in tight corners and hard-to-reach areas.

2. Grout Removal and Tile Installation:

When it comes to renovating or repairing tiled surfaces, oscillating tool saw blades prove their worth once again. The serrated or diamond-coated segment blades effortlessly cut through grout, allowing for swift and efficient removal. Furthermore, by utilizing the scraping or grout removal attachment, users can quickly extract old adhesives and prepare the tile bed without causing any damage. This versatility makes oscillating tool saw blades indispensable for tile installers and DIY tile projects alike.

3. Cutting Metal and Plastics:

While oscillating tool saw blades are renowned for their effectiveness in cutting wood and drywall, they are equally adept at handling metal and plastics. With the appropriate blade attachments, such as bi-metal or diamond grit blades, professionals can cut through various metals, including copper, aluminum, and steel, with ease. The precision and control provided by the oscillating motion allow for intricate cuts, making these blades invaluable in tasks like plumbing, electrical work, and metal fabrication.

4. Scraping and Stripping:

The scraping capabilities of oscillating tool saw blades open up a world of possibilities for professionals and hobbyists alike. Whether it is removing adhesive residue, stripping old paint, or scraping off caulk, the oscillating tool saw blades equipped with scraping attachments can tackle these arduous tasks effortlessly. The unique oscillating motion minimizes the risk of damage to surfaces, ensuring efficient and precise scraping.

5. Flush Cutting:

Achieving precise and flush cuts is often a challenge when working with wood, especially in tight spaces. Oscillating tool saw blades, with their unique design and oscillating motion, effortlessly resolve this challenge. Professionals, such as carpenters and flooring installers, can achieve clean and accurate cuts, including door jambs, baseboards, and intricate trim pieces, with ease. This versatility allows for seamless installations and eliminates the need for additional tools in cramped spaces.

Johnson Tools proudly showcases the vast potential of oscillating tool saw blades beyond their primary function of cutting. With their ability to sand, shape, remove grout, cut metal and plastics, scrape, strip, and perform flush cuts, these blades have become indispensable in numerous industries. From professional craftsmen and contractors to DIY enthusiasts, everyone can benefit from the versatility and efficiency offered by oscillating tool saw blades. Embrace the potential of innovation and let Johnson Tools elevate your creative possibilities.

Conclusion

1. Summary of key points: In this article, we have explored the versatility of oscillating tool saw blades in the realm of cutting-edge technology. From their unique design to their ability to tackle various materials with precision and efficiency, these tools have proven to be indispensable in a wide range of industries.

2. Practical applications: Throughout the discussion, we have highlighted the practical applications of oscillating tool saw blades. Whether you are a DIY enthusiast, a professional contractor, or someone working in the field of remodeling, these versatile blades can handle tasks such as plunge cutting, flush cutting, sanding, scraping, and much more.

3. Advanced features: Moreover, it is crucial to note the advanced features that make oscillating tool saw blades stand out. With interchangeable blades that can be easily swapped depending on the task at hand, these tools offer convenience and flexibility. Additionally, the multi-directional cutting action and adjustable speed settings allow for greater control and precision, ensuring excellent results.

4. Efficiency and time-saving benefits: Another important aspect to consider is the efficiency and time-saving benefits associated with oscillating tool saw blades. With their ability to quickly cut through various materials without the need for excessive force, these blades can significantly reduce project completion times. This not only enhances productivity but also allows for more projects to be tackled within a given timeframe, ultimately increasing profitability.

5. Cost-effectiveness: Furthermore, oscillating tool saw blades prove to be a cost-effective option for individuals and businesses alike. With their durability and long lifespan, these tools eliminate the need for frequent replacements, saving both time and money in the long run. Additionally, their versatility reduces the number of different tools needed for various tasks, further cutting down on expenses.

In conclusion, the versatility of oscillating tool saw blades is truly remarkable. From their ability to handle diverse materials and perform multiple functions, to their advanced features, efficiency, and cost-effectiveness, these cutting-edge tools have become an essential part of any toolkit. Whether you are a DIY enthusiast or a professional contractor, investing in oscillating tool saw blades will undoubtedly enhance your capabilities and bring your projects to a whole new level. So, embrace this cutting-edge guide and unlock the endless possibilities that oscillating tool saw blades have to offer.