Global Leading Diamond Tool Manufacturer.

Unlocking The Versatility Of Oscillating Tool Saw Blades: A Comprehensive Guide

Welcome to our comprehensive guide on unlocking the versatility of oscillating tool saw blades! If you're someone who loves tackling DIY projects or enjoys working with tools, this article is tailored just for you. In the world of power tools, oscillating tools have become increasingly popular due to their versatility and precision. However, an often overlooked aspect of these tools lies in the variety of saw blades available, each offering unique capabilities for a wide range of applications. Join us as we dive into the intricacies of oscillating tool saw blades, exploring their types, features, and how to harness their full potential. Whether you're a seasoned pro or new to the world of oscillating tools, this guide will provide you with valuable insights and tips to expand your tool arsenal and take your projects to the next level. So, grab your tool belt and let's harness the true potential of oscillating tool saw blades together!

Understanding Oscillating Tools: An Introduction to their Versatility

Oscillating tool saw blades are a revolutionary addition to the world of power tools, offering unmatched versatility in various tasks. In this comprehensive guide, we will dive into the world of oscillating tool saw blades, delving into their functionality, applications, and benefits. As a leading provider of high-quality tools, Johnsontools aims to educate and assist professionals and DIY enthusiasts in making the most of this remarkable tool accessory.

I. Understanding Oscillating Tools and Their Mechanism

Oscillating tools are handheld power tools that move their blades in rapid back-and-forth motions, known as oscillations. These tools operate with a versatile range of attachments, such as saw blades, enabling them to excel in a wide array of tasks, including cutting, sanding, scraping, and more. The unique oscillating motion of these tools ensures precise control and enhanced performance.

II. The Versatility of Oscillating Tool Saw Blades

A. Cutting Applications:

1. Woodworking: Oscillating tool saw blades are particularly useful in woodworking projects. They can effortlessly cut through different wood materials, including plywood, hardwood, and even composite boards. These blades come in various tooth patterns, such as fine-tooth, coarse-tooth, and Japanese-style blades, making them suitable for diverse woodworking tasks.

2. Metalworking: From light-gauge metals to copper pipes and nails, oscillating tool saw blades can handle a wide range of metal-cutting applications. Bi-metal blades are designed specifically for cutting through metal pipes, screws, and bolts with precision and reliability.

B. Other Applications:

1. Tile and Grout Removal: Oscillating tool saw blades equipped with carbide or diamond grit edges are perfect for efficiently removing old tiles and persistent grout lines. The oscillating motion helps minimize the risk of damage to adjacent tiles, ensuring clean and precise removal.

2. Sanding and Grinding: Various attachments, such as sanding pads and carbide rasps, allow oscillating tools to double as sanders and grinders. From smoothing rough surfaces to shaping curves, these versatile attachments make quick work of sanding, grinding, and shaping tasks.

3. Scraping and Caulking: With the appropriately designed scraping attachments, oscillating tool saw blades can easily remove old paint, adhesive, or caulk from surfaces. The oscillating motion ensures efficient and precise scraping, minimizing the effort required.

III. Benefits of Using Oscillating Tool Saw Blades

A. Versatility: Oscillating tool saw blades eliminate the need for multiple tools, as they can perform various tasks with just one tool. This versatility not only saves space but also reduces costs associated with purchasing multiple specialized tools.

B. Precision and Control: The oscillating motion of these tools provides excellent precision and control, allowing users to make intricate cuts and navigate tight spaces with ease.

C. Efficiency and Time-Saving: The swift oscillating motion of these tools significantly speeds up tasks compared to traditional cutting methods, reducing labor time and effort required.

D. Minimal Vibration and Noise: Oscillating tools are known for their quiet operation and low vibration, providing users with a comfortable working experience.

As we conclude this comprehensive guide, it is evident that oscillating tool saw blades are an invaluable addition to any toolbox. From woodworking and metalworking to tile removal and scraping, their versatility knows no bounds. With Johnsontools' commitment to delivering top-quality products, professionals and DIY enthusiasts can unlock the full potential of oscillating tools and achieve outstanding results in their projects.

Exploring the Different Types of Oscillating Tool Saw Blades

Oscillating tool saw blades are an essential component for any carpenter or DIY enthusiast. These versatile tools can cut through various materials, making them a must-have in any toolbox. In this comprehensive guide, we will dive deep into the world of oscillating tool saw blades, exploring the different types and their uses.

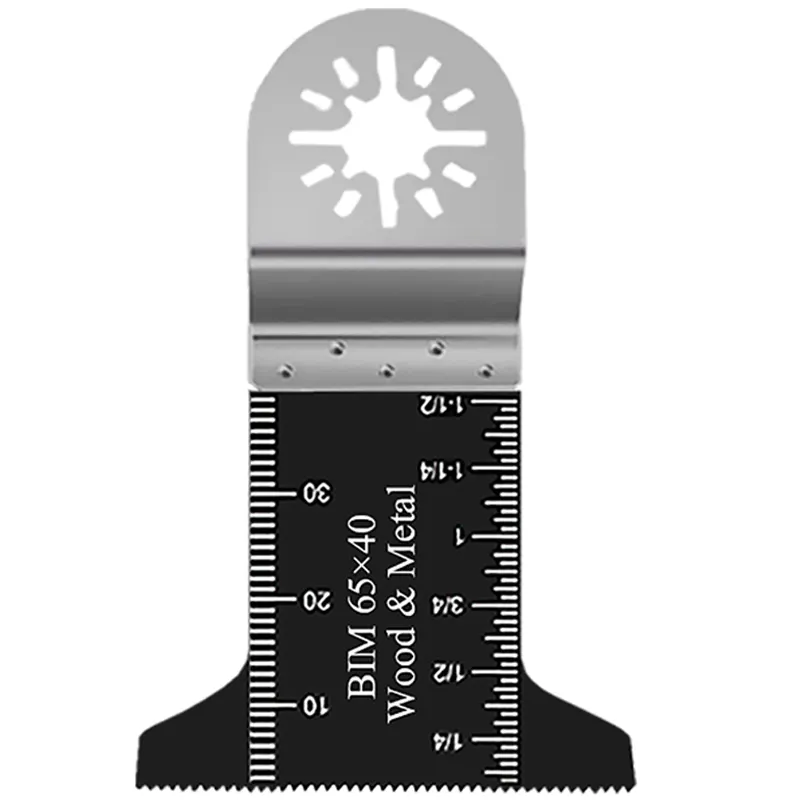

The first type of oscillating tool saw blade we will discuss is the bi-metal blade. This blade is made from two types of metal - high-speed steel and a flexible spring steel. This combination gives the blade incredible durability and allows it to cut through a wide range of materials. Bi-metal blades are perfect for cutting wood, nails, screws, copper pipes, and even thin metal sheets. The bi-metal blade from johnsontools is renowned for its longevity and superior cutting performance.

Next, let's talk about the carbide-tipped blade. This blade is designed for cutting through tough materials like hardwood, concrete, and fiberglass. The carbide teeth make the blade incredibly durable and resistant to wear. Whether you are working on a home renovation project or cutting through stubborn materials, the carbide-tipped blade from johnsontools will never let you down.

If you are working on a delicate project that requires precision cutting, the diamond grit blade is your best choice. This blade is designed to cut through hard materials like ceramic tiles, stone, and glass. The diamond grit coating on the blade ensures clean and precise cuts every time. With the diamond grit blade from johnsontools, you can achieve professional-level results in your DIY projects.

For those in need of a blade that can handle aggressive cutting tasks, the plunge-cutting blade is the ideal choice. This blade has a long and narrow shape, allowing it to make deep and precise cuts in various materials. It is perfect for tasks like cutting door jambs, trimming baseboards, or removing old grout. The plunge-cutting blade from johnsontools is engineered to deliver exceptional performance and durability, ensuring that your cutting tasks are completed with ease.

Lastly, we have the segmented blade. This blade is characterized by its evenly spaced segments, which allow it to cut through materials like wood, plastic, and drywall. The segmented blade from johnsontools is designed to provide efficient and precise cuts. It is ideal for tasks such as removing grout, cutting through pipes, or trimming door frames.

In summary, oscillating tool saw blades are an essential tool for any carpenter or DIY enthusiast. The different types of blades offer a wide range of solutions for various cutting tasks. Whether you need to cut through wood, metal, or even delicate materials like glass, there is a blade available to suit your needs. Johnsontools, 苏州乔盛进出口有限公司, is a trusted brand that offers high-quality oscillating tool saw blades for every cutting requirement. Invest in the right saw blade, and you can unlock the versatility and efficiency of your oscillating tool.

Selecting the Right Blade for the Job: Factors to Consider

As the old saying goes, "A craftsman is only as good as the tools they use." This holds particularly true when it comes to oscillating tool saw blades. Choosing the right blade for the job can make all the difference in the precision and efficiency of your work. In this comprehensive guide, we will explore the versatility of oscillating tool saw blades and provide you with valuable insights on how to make the right selection.

When it comes to oscillating tool saw blades, there is no one-size-fits-all solution. Different blades are designed for different purposes, materials, and cutting techniques. Understanding these factors will help you unlock the full potential of your oscillating tool to achieve outstanding results.

One of the primary considerations when selecting an oscillating tool saw blade is the material you will be working with. Blades are specifically designed to cut through various materials such as wood, metal, plastic, or a combination of them. Using the wrong blade for a specific material can lead to subpar performance and potentially damage both the blade and the material.

For cutting through wood, a bi-metal or high-speed steel (HSS) blade is recommended. These blades are designed with large teeth that have a deep gullet, allowing for efficient chip removal and reducing the risk of overheating. For metal cutting, a blade with carbide or diamond grit is preferred. These blades are specially designed to withstand the hardness of metals and provide clean and precise cuts.

Another important factor to consider is the cutting technique you will be using. Oscillating tool saw blades come in various designs, including standard tooth, plunge cut, flush cut, segmented, and grout cutting blades. Each design is intended for a specific cutting technique and provides unique benefits.

Standard tooth blades are the most commonly used blades and are suitable for general-purpose cutting. Plunge cut blades, as the name implies, are designed for plunge cuts and can easily create openings in materials like drywall or wood. Flush cut blades are perfect for precision cutting and can be used to trim door jambs or make flush cuts in moldings. Segmented blades are ideal for cutting through harder materials like nails, bolts, or pipes. Lastly, grout cutting blades are specifically designed to remove grout between tiles to aid in remodeling projects.

In addition to material and cutting technique, it is also crucial to consider the thickness of the blade for your specific application. Thicker blades are generally more durable and suitable for heavy-duty applications, while thinner blades offer increased flexibility and are ideal for making intricate cuts.

When selecting an oscillating tool saw blade, it is essential to choose one compatible with your oscillating tool model. Not all blades are universal and may vary in compatibility across different brands and models. Be sure to check the specifications of your tool and choose a blade that is compatible to avoid any compatibility issues or potential damage to your tool.

In conclusion, selecting the right blade for your oscillating tool is vital in achieving optimal performance and efficiency. Consider the material you will be working with, the cutting technique required, the blade's thickness, and the compatibility with your tool. By carefully considering these factors, you can unlock the true versatility of oscillating tool saw blades and elevate your craftsmanship to new heights.

Remember, for all your oscillating tool saw blade needs, trust Johnsontools – your reliable partner in quality tools.

Mastering Cutting Techniques with Oscillating Tool Saw Blades

Welcome to our comprehensive guide on mastering cutting techniques with oscillating tool saw blades, brought to you by Johnsontools. As a leading manufacturer and supplier in the industry, 苏州乔盛进出口有限公司, we are excited to share our expertise with you. In this article, we delve into the incredible versatility of oscillating tool saw blades and provide you with valuable tips and techniques to enhance your cutting prowess.

Exploring the Potential of Oscillating Tool Saw Blades:

Oscillating tool saw blades are widely renowned for their versatility and precision. From professional craftsmen to avid DIY enthusiasts, these blades have become a staple in workshops across various industries. However, to truly unlock their potential, it is imperative to understand the various cutting techniques and applications available.

1. Straight Cut Technique:

One of the most fundamental cutting techniques with oscillating tool saw blades is the straight cut. Whether you are working with wood, metal, or plastic, mastering this technique is essential. The key lies in keeping the blade perpendicular to the material and maintaining a steady hand movement. This technique is particularly useful for making clean and precise cuts in tight spaces and hard-to-reach areas.

2. Flush Cut Technique:

When it comes to cutting materials like pipes, baseboards, or trims, the flush cut technique comes in handy. By positioning the oscillating tool saw blade parallel to the surface, you can achieve a seamless and flush cut without damaging the adjoining material. This technique is ideal for renovation projects and detail-oriented tasks.

3. Plunge Cut Technique:

The plunge cut technique is perfect for creating precise openings or starting a cut in the middle of a material. By positioning the blade at the desired starting point and gently applying pressure, you can seamlessly penetrate the material and continue the cut in any desired direction. This technique is extremely useful for tasks such as creating electrical outlets, removing damaged flooring, or installing ventilation grills.

4. Curved Cut Technique:

For intricate and curved cuts, the oscillating tool saw blades offer exceptional control and maneuverability. By carefully guiding the blade along the desired path, you can effortlessly create curves, arcs, and even intricate designs. This technique finds great application in tasks such as shaping wood or making intricate cuts in fiberglass.

In conclusion, oscillating tool saw blades provide unparalleled versatility and precision in various cutting applications. By mastering the different techniques mentioned above, you can unleash the true potential of these blades and achieve professional-grade results. As a trusted brand in the industry, Johnsontools, 苏州乔盛进出口有限公司, takes pride in offering high-quality oscillating tool saw blades to meet the diverse needs of our customers.

So, whether you are a professional contractor or a passionate DIY enthusiast, we encourage you to explore the vast possibilities of oscillating tool saw blades and take your cutting skills to new heights. Remember, the key to success lies in practice and experimentation. Embrace the versatility and unleash your creativity with oscillating tool saw blades.

Tips and Tricks for Maintenance and Prolonging the Lifespan of Saw Blades

Keywords: Oscillating Tool Saw Blades

Brand: Johnsontools

Short Name: 苏州乔盛进出口有限公司

In the world of cutting tools, oscillating tool saw blades have gained immense popularity due to their versatility and effectiveness. Whether you are a professional craftsman or a DIY enthusiast, knowing how to properly maintain and prolong the lifespan of these blades is crucial. In this comprehensive guide, we will delve into the tips and tricks for maintenance and explore the world of oscillating tool saw blades.

Understanding Oscillating Tool Saw Blades:

Oscillating tool saw blades are unique cutting tools that work by rapidly oscillating side to side, rather than rotating like traditional saws. They are incredibly versatile, capable of tackling a wide range of materials including wood, metal, plastic, and even drywall. These blades are available in various shapes and sizes, allowing them to perform intricate cuts and access tight spaces effortlessly.

Maintenance Tips for Oscillating Tool Saw Blades:

1. Clean the Blades Regularly: After each use, it is essential to clean the blades thoroughly to remove any residue or buildup. Use a brush or compressed air to remove dust and debris from the teeth of the blades.

2. Lubricate the Blades: Applying a thin layer of lubricant to the blades helps reduce friction and prolongs their lifespan. Use a high-quality lubricant recommended by the manufacturer, ensuring that it is specifically designed for oscillating tool saw blades.

3. Avoid Excessive Force: While oscillating tool saw blades are durable, it is important to avoid exerting excessive force. Let the blade do the work and avoid pushing or twisting it vigorously, as this can lead to premature wear and potential blade damage.

4. Store Properly: After each use, store the saw blades in a clean and dry place. Use blade guards or protective sleeves to prevent accidental damage and ensure they are not exposed to moisture or other harmful elements.

Prolonging the Lifespan of Oscillating Tool Saw Blades:

1. Choose the Right Blade for the Material: Different materials require specific types of blades. Using the correct blade for the job reduces strain on the blade and prolongs its lifespan. Consult the manufacturer's recommendations or seek expert advice to ensure you are using the right blade for the material.

2. Monitor Blade Temperature: Continuous use of oscillating tool saw blades can lead to heat buildup, which can decrease their efficiency and durability. Monitor the temperature of the blade while cutting and take breaks if necessary to prevent overheating.

3. Sharpen or Replace Blades when Needed: Blades eventually wear out and become dull over time. It is crucial to regularly check the sharpness of the blades and sharpen or replace them as needed. Dull blades not only affect the quality of the cut but also increase the risk of accidents.

4. Use Cutting Guides: To ensure accurate and precise cuts, consider using cutting guides or templates. These tools not only enhance the efficiency of the cutting process but also reduce strain on the blades, resulting in a longer lifespan.

Oscillating tool saw blades are invaluable cutting tools with immense versatility. Proper maintenance and care are essential for maximizing their lifespan and ensuring optimal performance. By following the tips and tricks outlined in this comprehensive guide, you can unlock the full potential of your oscillating tool saw blades and achieve professional-quality results every time. Remember, Johnsontools (苏州乔盛进出口有限公司) is your trusted partner in the world of cutting tools, providing you with the highest quality products to meet all your cutting needs.

Conclusion

1. Practical applications: Highlight the various ways oscillating tool saw blades can be used in everyday tasks, from home renovations to DIY projects. Emphasize the versatility and ease of use, allowing readers to confidently tackle any cutting or sawing job with efficiency.

2. Benefits and advantages: Discuss the advantages of using oscillating tool saw blades compared to traditional saws or power tools. Mention their ability to access tight spaces, make precise cuts, and reduce the risk of accidental damage. Explain how these blades can save time and effort, making them a valuable addition to any toolbox.

3. Expert recommendations: Refer to the expertise shared in the article and the comprehensive guide provided. Encourage readers to experiment with different blade types, materials, and techniques mentioned, as it can unlock a world of possibilities for their projects. Mention how the insights in this guide will enable readers to make informed decisions when selecting the right oscillating tool saw blades for their specific needs.

4. The future outlook: Briefly touch upon the potential advancements and developments in oscillating tool saw blades. Highlight any emerging technologies or trends that could enhance their versatility in the future. This will leave readers with a sense of excitement and anticipation for what lies ahead in the world of oscillating tool saw blades.

Overall, conclude by reiterating the importance of oscillating tool saw blades as an essential tool in any DIY enthusiast or professional's arsenal. Encourage readers to explore and experiment with the diverse applications of these blades, knowing they have a reliable resource to rely on when seeking guidance.