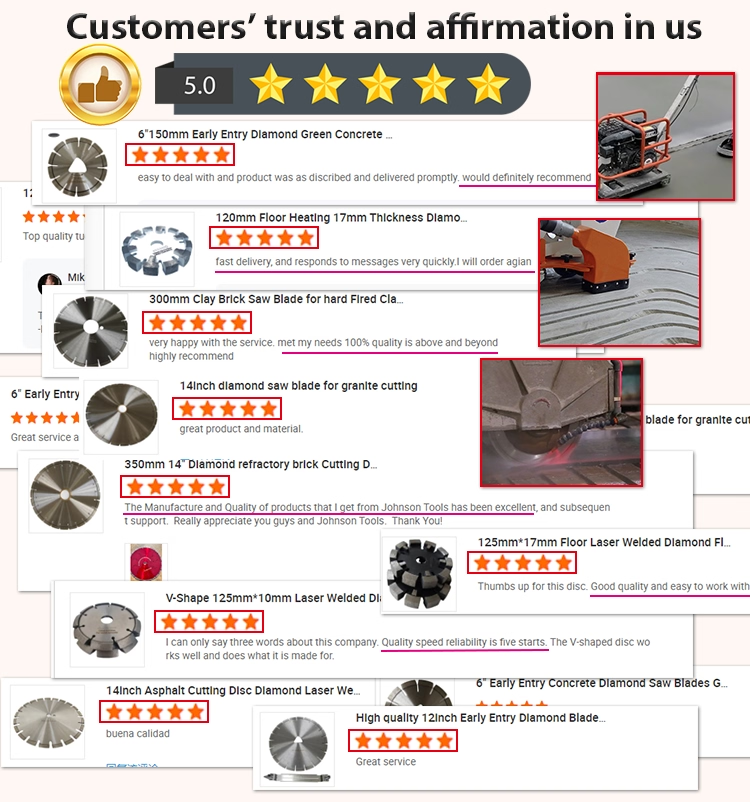

Quality is well accepted by the customers.

Global Leading Diamond Tool Manufacturer.

Johnson Tools Laser Welding Diamond Saw Blade With Turbo Segment Diameter 105-230mm Cutting Discs For General Purpose

Specifications:

Blade Diameter: 4"/105mm, 4.5"115mm, 5"/125mm, 7"/180mm, 9"/230mm

Arbor Size: 20/22.23 mm or as your request

Segment Height: 10/12mm

Segment Thickness: 2.2mm, 2.4mm, 2.6mm

Technology: Laser Welding saw blade

Color:Color or as your request

Cutting Materials: Specially design for dry cutting Concrete, Brick, Granite, Sandstone, etc.

Operating Conditions: Suitable for wet and dry cutting

Designed for versatility and safety, the Johnson Tools Laser Welded Diamond Blade features Turbo Segments for aggressive cutting speeds. The high-strength laser weld ensures segments remain attached even under extreme heat, making it the safest choice for dry cutting reinforced concrete, hard brick, and natural stone with handheld angle grinders.

Get In Touch With Us

PRODUCT ADVANTAGES

Our customer service team is a dedicated, hard-working group specially selected for their enthusiasm and commitment to providing excellent customer service. They offer advice, answer any queries.

PRODUCT parameter

| Diameter (mm) | Hole (mm) | Segment size (mm) |

| 4"/105mm | 20 | 31.5x2.2x10/12 |

| 4.5"/115mm | 20 | 31.5x2.2x10/12 |

| 5"/125mm | 20 | 31.5x2.2x10/12 |

| 7"/180mm | 22.23 | 30x2.4x10/12 |

| 9"/230mm | 22.23 | 30x2.6x10/12 |

| Customizable | ||

product usage

Versatile Diamond Saw Blade:

Concrete Cutting Saw Blades are professionally designed for wet or dry cutting reinforced concrete, high quality diamond makes faster cuting and longer cutting life.

Noteworthy Features:

Focus on diamond tools products

One-Stop OEM/ODM solution for diamond tools field

Strictly detection from raw materials to shipping

High precision and speed for cutting Cured concrete

Cutting cured concrete is not restricted by the construction site, environmental protection, duration, and other conditions for safety reasons, to break the traditional construction method after removal of gas cutting picks or directional blasting, which does not affect the surrounding normal traffic, short construction period, safety factor advantages.

Laser welding diamond saw blade is our advantage product

Usually designed for asphalt, asphalt overlay, and other abrasives material cutting with high efficiency

"Laser welding for diamond saw blades offers high precision, reliable strength, non-destructive welding, energy efficiency, and fine control, optimizing production processes and extending blade lifespan."

RELATED PRODUCTS

Recommend more related products for you, you can choose the right product for supporting purchases