Global Leading Diamond Tool Manufacturer.

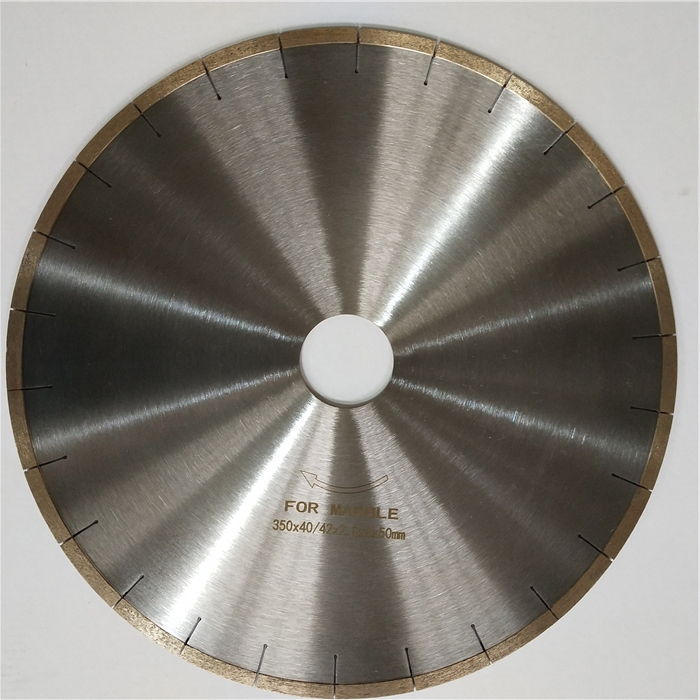

Johnson Tools 14'' High Frequency Welded Diamond Cutting Blade for Marble

Get In Touch With Us

PRODUCT ADVANTAGES

Our customer service team is a dedicated, hard-working group specially selected for their enthusiasm and commitment to providing excellent customer service. They offer advice, answer any queries.

product usage

Safety Precautions:

Prioritize safety by wearing appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and gloves, to minimize the risk of injury.

Depth of Cut:

Adjust the depth of cut based on the thickness of the marble slab. Cutting too deeply can strain the blade and the saw, while shallow cuts may result in incomplete cuts or chipping.

Why Choose Our 14" Marble Blade?

Chip-Free Precision: Marble is delicate and prone to chipping. Our specialized segment bond is formulated to cut smoothly through the stone's calcite structure, leaving a razor-sharp edge that requires minimal polishing.

High Frequency Welded Safety: Unlike standard sintered blades, our segments are welded using high-frequency induction. This provides a superior bond strength that withstands the lateral forces of bridge sawing, preventing segment loss.

Extended Lifespan: Featuring 10mm high segments, this blade offers a long service life, reducing the frequency of blade changes and lowering your cost per cut.

Optimized Dimensions: With a 2.8mm thin kerf, it minimizes material waste and cutting resistance, allowing for faster feed rates on your bridge saw.

RELATED PRODUCTS

Recommend more related products for you, you can choose the right product for supporting purchases