Global Leading Diamond Tool Manufacturer.

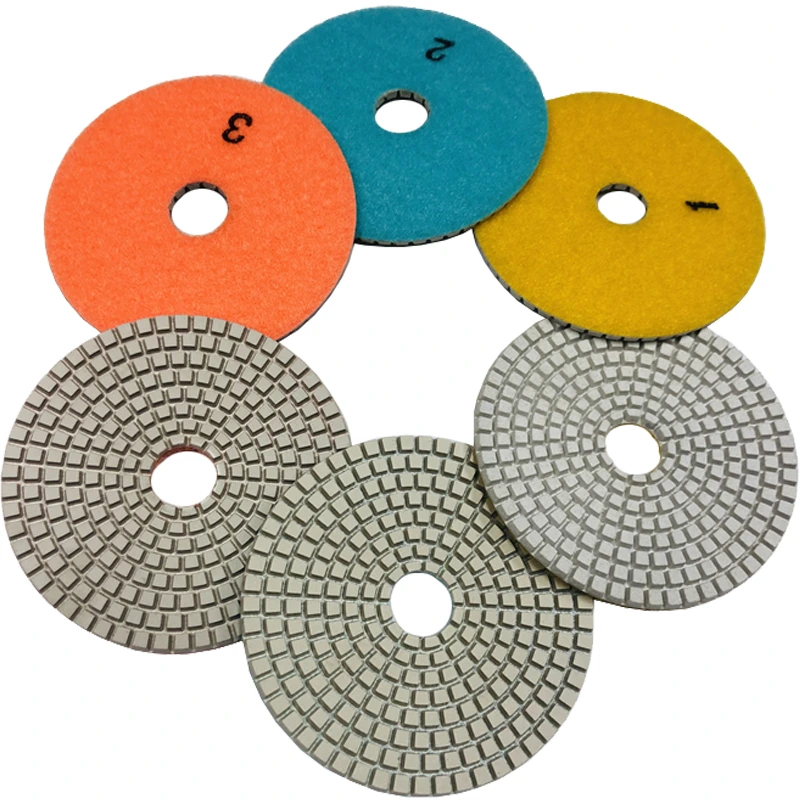

Johnson Tools 3 Steps 100mm Wet Flexible Round Resin Binded Polishing Pads for Granite Stone Set

Specifications:

Size: 4inch(100mm)

Type: 3step

Material: Resin bond with diamond

Color: White

Usage: Wet

Versatile Polishing:

Tailored for granite, marble, and various other stones, these pads are your go-to choice for achieving a flawless polish. The versatility allows you to handle different stone materials with ease.

Convenient 3-Step Polishing:

Simplify your polishing process with the convenience of three steps. These pads make polishing easy, providing a seamless transition from one step to the next.

Get In Touch With Us

PRODUCT ADVANTAGES

Our customer service team is a dedicated, hard-working group specially selected for their enthusiasm and commitment to providing excellent customer service. They offer advice, answer any queries.

Coarse Grit (Step 1):

Purpose: This initial step is the coarsest among the three. It focuses on removing rough imperfections, scratches, and any uneven surfaces from the granite.

Grit Size: Typically, a lower grit size is used in this step, such as 50 or 100.

Action: The coarse grit pads work to level the surface and prepare it for finer polishing. They are instrumental in the initial shaping and smoothing of the granite.

Medium Grit (Step 2):

Purpose: The medium-grit step follows the coarse grit and aims to refine the surface further. It addresses the smaller scratches and imperfections left from the first step.

Grit Size: The grit size in this step is higher than the coarse grit but still lower than the final polishing step. It might range from 200 to 400, depending on the specific pads.

Action: The medium grit pads continue the smoothing process, gradually eliminating the coarser marks and creating a more polished appearance.

Fine Grit (Step 3):

Purpose: The final step involves fine grit polishing to achieve a smooth and highly polished surface. It's intended to remove any remaining fine scratches, enhance the color, and bring out the natural shine of the granite.

Grit Size: This step employs the highest grit size in the sequence, often ranging from 800 to 3000 or more.

Action: The fine grit pads provide the finishing touches, delivering a glossy and reflective surface. They contribute to the granite's overall brilliance and clarity.

PRODUCT parameter

| OD size | Thickness(mm) | Grit size |

| 3 inch(75mm) |

2.5-3.0 |

#50, #100, #200, #400, #800, #1500, #3000 and buff-black or white |

| 4 inch(100mm) | 2.5-3.0 | |

| 5 inch(125mm) | 2.5 | |

| 6 inch(150mm) | 3.0 | |

| 7inch(180mm) | 3.0 |

product usage

Applications:

Surface Polishing: Suitable for the surface polishing of large concrete floors, enhancing overall aesthetics.

Scratch Repair: Ideal for repairing minor scratches on the surface of concrete

RELATED PRODUCTS

Recommend more related products for you, you can choose the right product for supporting purchases