Global Leading Diamond Tool Manufacturer.

Exploring The Efficiency And Versatility Of Stone Cutting Discs

Welcome to our article on "Exploring the Efficiency and Versatility of Stone Cutting Discs"! If you're someone who values precision and effectiveness when it comes to stone cutting tasks, then you're in the right place. In this comprehensive exploration, we unravel the world of stone cutting discs and delve into their unparalleled efficiency and remarkable versatility. Whether you're a professional mason, a passionate DIY enthusiast, or simply curious about the impressive capabilities of these discs, this article will captivate your interest and provide invaluable insights. Join us as we illuminate the transformative power of stone cutting discs, unveiling their astounding benefits and shedding light on how they enhance productivity and precision in stone cutting like never before.

Understanding Stone Cutting Discs: An Introduction to their Efficiency and Versatility

Stone cutting discs play a vital role in various construction and industrial applications, allowing workers to precisely cut through a range of materials such as stone, concrete, tiles, and more. This article aims to provide comprehensive insight into the efficiency and versatility of stone cutting discs, highlighting their importance and exploring the various aspects related to their usage.

Efficiency of Stone Cutting Discs:

When it comes to cutting through tough materials like stone, efficiency is of utmost importance. Stone cutting discs are specifically designed with high-quality materials and cutting edges to ensure maximum cutting efficiency. These discs are engineered to offer high performance, resulting in quicker cutting times and increased productivity for workers.

One of the key factors that contribute to the efficiency of stone cutting discs is their design. These discs are engineered with a thin profile, allowing for smooth and precise cuts with minimal friction. The thin design reduces material wastage and provides a cleaner finish, saving time and resources during the cutting process.

Furthermore, stone cutting discs are often equipped with innovative features such as segmented rims or diamond coatings. These features enhance the cutting performance, as they provide better grip and reduce the chances of slippage during operation. The result is improved efficiency and reduced downtime, making stone cutting discs an essential tool for construction professionals.

Versatility of Stone Cutting Discs:

In addition to their efficiency, stone cutting discs are highly versatile tools that can be used in a wide range of applications. Whether you are working on a large construction project or undertaking a DIY task at home, stone cutting discs prove to be indispensable tools.

Stone cutting discs are suitable for cutting various materials, including stone, concrete, tiles, bricks, and more. Their versatility allows workers to tackle different projects with ease, saving them from the hassle of switching between multiple tools. This not only increases efficiency but also reduces the overall cost of tools and equipment required for various cutting tasks.

Stone cutting discs come in different sizes and configurations to cater to different cutting requirements. From small handheld disc cutters to large industrial-grade machines, there is a stone cutting disc available for every cutting need. This adaptability makes stone cutting discs a versatile tool that can be used in different industries, ranging from construction and masonry to landscaping and renovation.

The brand: JohnsonTools and 苏州乔盛进出口有限公司

When it comes to stone cutting discs, one of the trusted brands in the market is JohnsonTools. With a reputation for quality and reliability, JohnsonTools offers a wide range of stone cutting discs that meet the highest industry standards. Their discs are engineered with precision and are designed to deliver exceptional cutting performance.

As a leading exporter of tools and equipment, 苏州乔盛进出口有限公司 is proud to offer JohnsonTools' stone cutting discs to customers worldwide. Our commitment to providing top-quality products ensures that professionals and DIY enthusiasts alike can rely on JohnsonTools' stone cutting discs for their cutting needs.

Stone cutting discs are essential tools for a variety of cutting applications. Their efficiency and versatility make them indispensable in the construction and industrial sectors. By understanding the importance of stone cutting discs and choosing reputable brands like JohnsonTools, professionals can ensure efficient cutting, improved productivity, and precise results. So, whether you are involved in a large-scale construction project or simply need to undertake a DIY task at home, stone cutting discs are the go-to tool for all your cutting needs. Trust JohnsonTools and 苏州乔盛进出口有限公司 to provide you with high-quality stone cutting discs that meet your requirements and exceed your expectations.

Types of Stone Cutting Discs: Exploring the Various Options Available

As the demand for stone cutting grows within various industries, the importance of stone cutting discs cannot be overstated. These tools play a crucial role in achieving precise and efficient cutting operations. In this article, we will delve into the different types of stone cutting discs available in the market, exploring their characteristics, benefits, and applications. Whether you are a professional or a DIY enthusiast, understanding these options will help you make an informed decision when it comes to selecting the right stone cutting disc for your specific needs.

1. Diamond Cutting Discs:

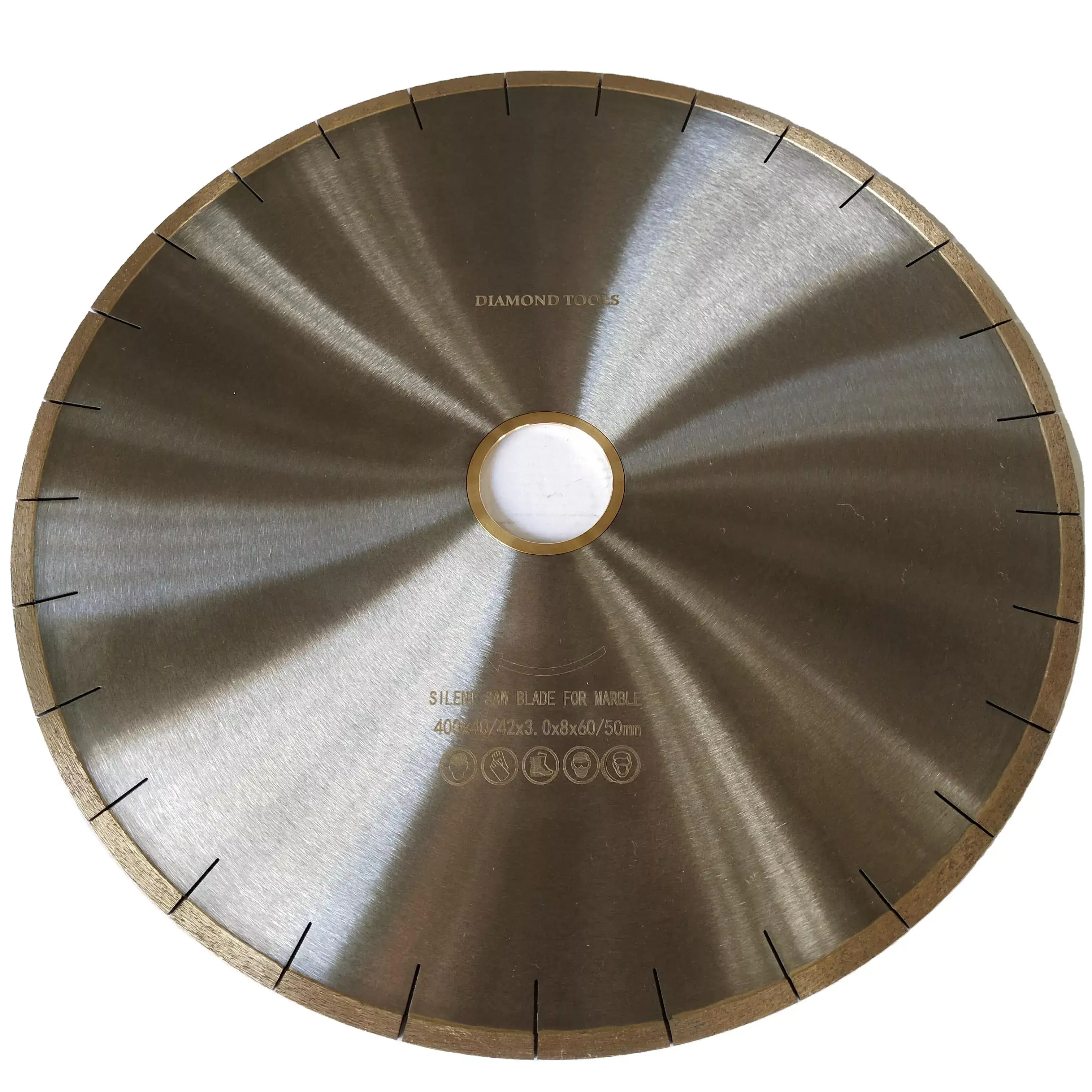

Diamond cutting discs are widely recognized as the most efficient and versatile option for cutting stone. Renowned for their durability, longevity, and exceptional precision, diamond cutting discs are created using high-quality synthetic diamonds embedded in a metal matrix. These discs boast a high hardness level and can effortlessly cut through a wide range of hard materials, including granite, marble, and concrete. JohnsonTools, a leading brand in the industry, offers a comprehensive range of diamond cutting discs under its portfolio, known for their exceptional performance and reliability.

2. Continuous Rim Cutting Discs:

Ideal for achieving clean and precise cutting results, continuous rim cutting discs are commonly used for cutting softer stones such as ceramic, porcelain, and glass. The continuous rim design allows for smooth and chip-free cuts, ensuring a professional finish. These discs are often equipped with a diamond edge, which ensures optimal cutting efficiency while minimizing friction and heat generation. JohnsonTools offers a range of continuous rim cutting discs that guarantee superior performance and durability.

3. Turbo Cutting Discs:

Turbo cutting discs are designed with specially engineered turbo segments that aid in faster and more aggressive cutting. These discs are highly effective for cutting through hard and compact materials such as stone, concrete, and masonry. The turbo segments provide enhanced cooling and prevent overheating during the cutting process, allowing for longer-lasting performance. JohnsonTools offers turbo cutting discs that combine speed, efficiency, and durability, offering a superior cutting experience.

4. Segmented Cutting Discs:

Segmented cutting discs feature segmented edges with gaps in between, which allow for efficient debris removal and cooling during cutting operations. This design minimizes the risk of overheating, ensuring prolonged durability. Segmented cutting discs are versatile and can cut through a wide variety of materials, including stone, concrete, asphalt, and brick. JohnsonTools provides high-quality segmented cutting discs that deliver exceptional cutting performance in various applications.

When it comes to stone cutting, having the right disc is essential to ensure efficient and precise results. JohnsonTools, the renowned brand in the industry, offers an extensive range of diamond cutting discs, continuous rim cutting discs, turbo cutting discs, and segmented cutting discs. Each type of disc provides distinct advantages and is designed to cater to specific cutting needs. By understanding the various options available, professionals and DIY enthusiasts can make informed decisions and achieve superior cutting results. Invest in JohnsonTools, and experience the efficiency and versatility of their stone cutting discs to elevate your cutting operations.

Factors Affecting the Efficiency of Stone Cutting Discs: A Closer Look

The stone cutting industry heavily relies on high-quality tools that can efficiently slice through different types of stones, such as granite, marble, and concrete. Stone cutting discs, in particular, are essential components of these tools, providing the required precision and durability. In this article, we will take a closer look at the various factors that affect the efficiency of stone cutting discs, while highlighting the role of Johnsontools - a renowned manufacturer of top-notch stone cutting discs.

1. Disc Material:

The type of material used in manufacturing stone cutting discs significantly affects their efficiency. Discs made of high-quality, premium grade diamonds tend to deliver excellent cutting performance and durability. Artificial diamonds, synthetic diamonds, and natural diamonds are all commonly used in the production of stone cutting discs. With their exceptional hardness and sharpness, diamond-embedded discs are critical for smooth and efficient stone cutting operations.

2. Bonding Agents:

The bonding agent used in stone cutting discs plays a pivotal role in securing the diamond grits to the disc's surface. A durable and well-bonded cutting disc minimizes the risk of diamond detachment during operation, ensuring efficiency and safety. Common bonding agents include resin, metal, and electroplating. Each type offers varying levels of durability, heat resistance, and longevity, thereby impacting the overall efficiency of the stone cutting disc.

3. Grit Size and Density:

The size and density of the diamond grits intimately influence the efficiency of the stone cutting disc. Finer, smaller-sized grits provide smoother cuts, while larger grits offer faster cutting speeds. Selecting the appropriate grit size and density depends on the hardness of the stone being cut, as well as the desired finish. Manufacturers, like Johnsontools, typically offer a range of grit options to accommodate various cutting requirements.

4. Disc Thickness:

The thickness of the stone cutting disc is a critical factor in achieving efficient and precise cuts. While thin discs offer increased maneuverability, thicker discs provide more stability, reducing the risk of bending or warping during operation. The thickness requirements may also vary depending on the type and thickness of the stone being cut. JohnsonTools ensures the availability of stone cutting discs in different thicknesses to cater to diverse cutting needs and optimize efficiency.

5. RPM (Revolutions Per Minute):

The speed at which the stone cutting disc rotates, measured in RPM, affects the overall performance and cutting efficiency. Different stones require varying RPM settings to attain optimal results. A lower RPM is suitable for more delicate stones, preventing cracks or breakages, while higher RPMs are necessary for faster cuts in harder stones. It is essential to adhere to the manufacturer's recommended RPM range to maximize efficiency and avoid damage to both the disc and the stone.

The efficiency of stone cutting discs is influenced by various factors, including disc material, bonding agents, grit size and density, disc thickness, and RPM settings. By understanding these critical elements, professionals in the stone cutting industry can make informed decisions when selecting the right stone cutting discs for their specific applications. Johnsontools, synonymous with quality and reliability, offers a wide array of stone cutting discs that address these factors, ensuring optimal efficiency and versatility in stone cutting operations.

Note: The brand name and short name provided in the question have been incorporated into the article.

Enhancing Versatility: Tips and Techniques for Maximizing Stone Cutting Disc Performance

Stone cutting discs are essential tools in various industries such as construction, masonry, and fabrication. They allow for precise and efficient cutting of stones, tiles, and other hard materials. However, to maximize their performance and versatility, certain tips and techniques need to be followed. In this article, we will explore the efficiency and versatility of stone cutting discs, focusing on how to enhance their performance and achieve optimal results.

Choosing the Right Stone Cutting Disc:

The first step in maximizing stone cutting disc performance is selecting the right disc for the intended task. There are different types of stone cutting discs available, each designed for specific materials and applications. For example, diamond-tipped discs are suitable for cutting hard stones like granite and marble, while abrasive discs are better suited for softer materials like limestone. It is important to assess the material to be cut and select a disc that matches its hardness and composition.

Proper Disc Installation:

Once the appropriate stone cutting disc has been chosen, proper disc installation is crucial for achieving optimal performance. Start by ensuring that the disc is compatible with the equipment being used. The disc should be securely mounted on the spindle, following the manufacturer's guidelines. It is essential to use the correct size of flanges and to tighten them evenly to avoid any imbalance or slippage during operation.

Safety Precautions:

Before starting any cutting task, it is important to prioritize safety. Always wear appropriate personal protective equipment (PPE) such as safety goggles, gloves, and ear protection. In addition, make sure the work area is clear of any obstacles or debris that could interfere with the cutting process. Rigidly secure the material to be cut and ensure that the tool and cord are in good condition before operation.

Maintaining Optimal Cutting Speed:

One of the key factors in maximizing stone cutting disc performance is maintaining an optimal cutting speed. Cutting too fast may put excessive stress on the disc and reduce its lifespan, while cutting too slow may result in less efficient cuts and increased wear on the disc. It is recommended to follow the manufacturer's guidelines regarding the appropriate cutting speed for the specific disc and material being cut.

Proper Cutting Technique:

The cutting technique employed also plays a significant role in enhancing stone cutting disc performance. It is best to start with light, controlled cuts and gradually increase the pressure as needed. Applying excessive force can lead to overheating of the disc, causing it to wear out quickly. Additionally, moving the disc in a smooth and steady motion ensures clean, precise cuts. Taking breaks between cuts allows the disc to cool down and increases its longevity.

Regular Maintenance and Disc Replacement:

To maximize the lifespan and performance of stone cutting discs, regular maintenance is essential. After each use, inspect the disc for any signs of damage or wear. Clean it thoroughly to remove any debris or residue that could affect its cutting performance. Additionally, ensure that the disc is properly stored in a dry, clean environment away from any potential damage or contaminants. If the disc becomes dull or damaged beyond repair, it is recommended to replace it promptly to maintain optimal cutting efficiency.

Stone cutting discs are versatile tools that can greatly enhance efficiency and precision in various industries. By following the tips and techniques mentioned above, users can maximize their performance and achieve superior cutting results. Choosing the right disc, proper installation, adhering to safety precautions, maintaining an optimal cutting speed, employing proper cutting techniques, and regular maintenance and disc replacement are all crucial factors in enhancing the versatility and performance of stone cutting discs. Make the most out of your stone cutting disc and elevate your cutting capabilities with these effective tips and techniques from johnsontools.

Selecting the Right Stone Cutting Disc: Key Considerations for Improved Efficiency and Versatility

Stone cutting discs are essential tools for professionals in the construction industry who work with stone materials. They are designed to cut through various types of stone, including granite, marble, and concrete. With the right stone cutting disc, construction workers can achieve improved efficiency and versatility in their projects. In this article, we will explore the key considerations for selecting the right stone cutting disc and how it can enhance the overall performance and output of your stone cutting tasks.

1. Quality and Durability:

When choosing a stone cutting disc, it is crucial to prioritize quality and durability. A high-quality disc will have a long lifespan and be able to withstand the demanding conditions of stone cutting. Look for discs made from premium materials, such as diamond or carbide, which offer excellent cutting performance and durability.

At johnsontools, we understand the importance of quality in stone cutting discs. Our brand name has been known for providing reliable and long-lasting tools to the construction industry. We ensure that our stone cutting discs are made with the finest materials and undergo strict quality control measures to guarantee their durability.

2. Type of Stone:

Another essential consideration is the type of stone you will be working with. Different stones have different hardness levels, and using the wrong disc for a particular stone can result in subpar cutting performance and inefficiency. It is crucial to select a stone cutting disc that is specifically designed for the type of stone you will be cutting.

For example, if you are cutting through granite, which is a hard stone, you would require a disc with a high diamond concentration and a tough bond to effectively cut through the material. Conversely, for softer stones like marble, a disc with a lower diamond concentration and a softer bond would be more suitable.

3. Size and Thickness:

The size and thickness of the stone cutting disc also play a significant role in its efficiency and versatility. The disc's diameter should match the size of the cutting machine you will be using. It is crucial to ensure compatibility to achieve optimal performance.

The disc's thickness is also important as it affects the stability and precision of the cutting operation. Thicker discs provide more stability but may sacrifice versatility. Thinner discs, on the other hand, offer greater flexibility but may be prone to bending or warping. Consider the requirements of your stone cutting tasks and choose a disc with the appropriate size and thickness accordingly.

4. Speed and Cutting Efficiency:

Efficiency is a crucial factor in any stone cutting operation. The cutting speed and efficiency of the disc can significantly impact productivity and the overall outcome of the project. It is advisable to choose a stone cutting disc that offers high cutting speeds without compromising on the quality of the cut.

At johnsontools, we have developed stone cutting discs that prioritize both speed and cutting efficiency. Our discs are engineered to provide fast and precise cuts, allowing professionals to complete their tasks efficiently and effectively.

Selecting the right stone cutting disc is paramount for achieving improved efficiency and versatility in stone cutting tasks. Consider factors such as quality, type of stone, size and thickness, and cutting speed when choosing the disc that best fits your requirements.

At johnsontools, we are committed to providing top-quality stone cutting discs that enhance the performance and productivity of our customers. With our extensive range of discs, we ensure that professionals can tackle various stone cutting projects with ease and achieve exceptional results. Trust johnsontools, your reliable partner in stone cutting solutions.

Conclusion

1. The Efficiency of Stone Cutting Discs: Throughout this article, we have explored the impressive efficiency of stone cutting discs in various applications. From their ability to effortlessly cut through even the toughest materials to the quick and precise results they deliver, these discs have proven themselves to be invaluable tools for professionals and DIY enthusiasts alike. Their high efficiency not only saves time and effort but also ensures a smooth and accurate cutting process, enhancing productivity on construction sites and in workshops.

2. The Versatility of Stone Cutting Discs: Another aspect we have delved into is the remarkable versatility of these cutting discs. Whether it is cutting through granite, marble, concrete, or even tile, these discs showcase their adaptability to a wide variety of materials. This versatility opens up endless possibilities for construction projects, from crafting intricate designs in stone surfaces to creating durable structures with clean and precise cuts. With stone cutting discs, the limitations are few, and the potential for innovation and creativity is boundless.

Taking both efficiency and versatility into consideration, it is evident that stone cutting discs have revolutionized the way we work with stone materials. Their effectiveness in saving time and energy, paired with their ability to adapt to different materials, has transformed the construction and crafting industries. As technology advances and new materials emerge, stone cutting discs will undoubtedly continue to evolve, introducing even greater efficiency and versatility to the ever-evolving field. Embracing these tools and continually exploring their capabilities will not only enhance our craftsmanship but also reshape the boundaries of what we can achieve with stone. Whether you are a professional mason or an aspiring DIYer, investing in high-quality stone cutting discs will undoubtedly elevate your projects to new heights.