Global Leading Diamond Tool Manufacturer.

Guide to Selecting Stone Cutting Discs by Working Principle

Imagine a homeowner preparing for a DIY project, like cutting a stone countertop. Understanding the right stone cutting disc is crucial for precision and durability. In this guide, well delve into the key working principles of stone cutting discs to help you make informed decisions.

Understanding the Working Principles of Stone Cutting Discs

Understanding the working principles is key to choosing the right disc for your project. Here are the main types and their unique benefits:

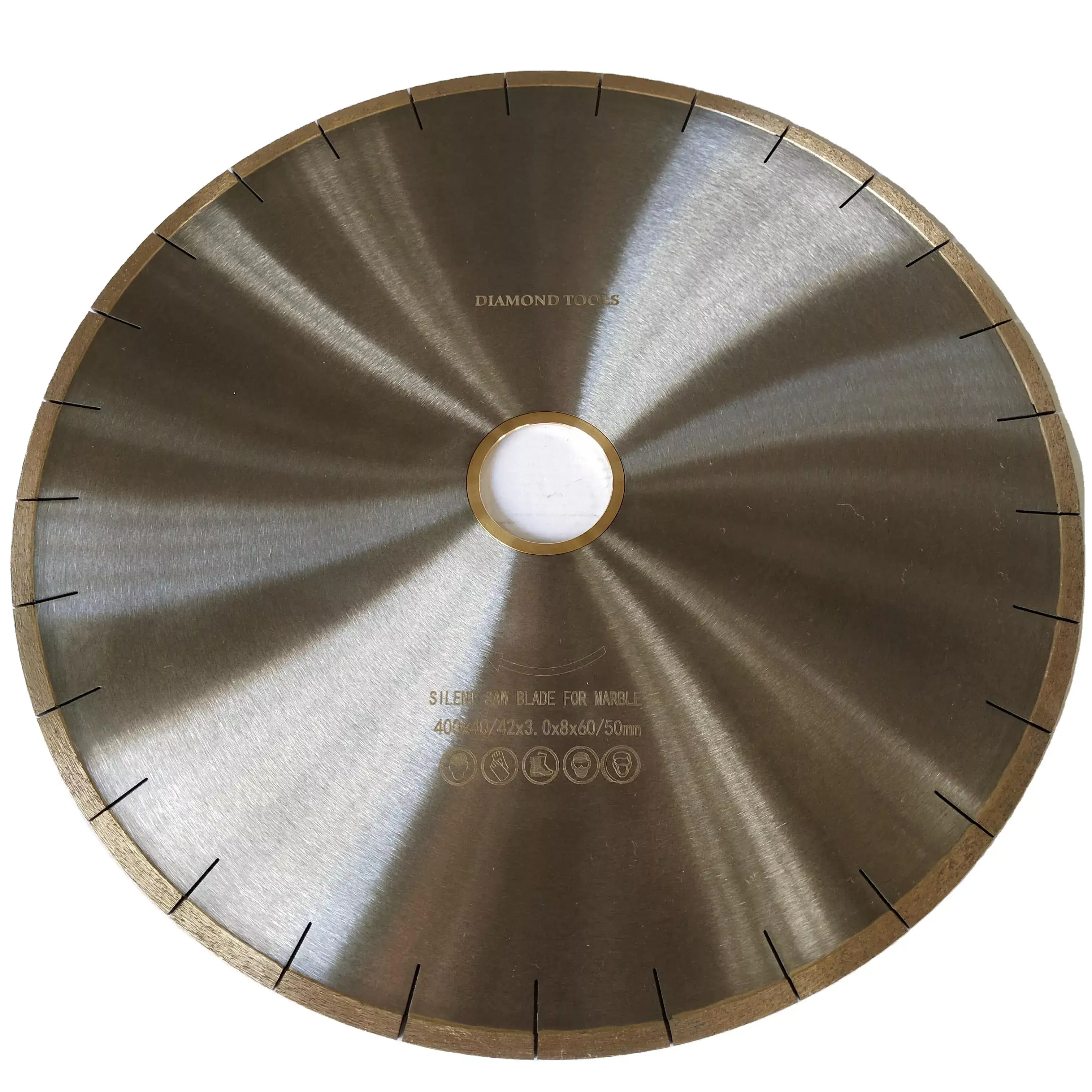

- Abrasive Materials: These discs are made of bonded abrasive particles, like silicon carbide or diamond, embedded in a resin matrix. They are perfect for harder stones like granite and marble, providing durability and minimal dust.

- Diamond Discs: Made exclusively of synthetic or natural diamonds, these discs excel at cutting softer stones like travertine and onyx. They produce a smooth, even finish but can be more expensive.

- Abrasive-Bonded Discs: A mix of abrasive particles and resin, these discs are lightweight and flexible, ideal for softer stones like soapstone and slate. However, they may wear out faster.

By knowing these key principles, you can choose the best disc for your specific needs.

Material Compatibility and Abrasive Selection

Selecting the right disc depends on the stone type and its properties:

- Hard Stones (e.g., granite, marble): Opt for diamond or abrasive discs. These handle hard stones well while maintaining precision and durability.

- Soft Stones (e.g., soapstone, slate): Use abrasive-bonded discs, which are lighter and more flexible.

- Decorative Stones (e.g., onyx, travertine): Choose diamond discs for smooth and even finishes. Ensure the discs abrasive material matches the stones hardness.

For instance, if youre working with marble, a diamond disc will ensure a clean and precise cut. If youre dealing with soapstone, an abrasive-bonded disc is a safer bet.

Edge Geometry and Its Impact on Stone Cutting

The edge geometry of a stone cutting disc significantly affects how efficiently and precisely you can cut:

- V-Edge: Minimizes kerf and ensures even chip removal, ideal for precision cutting. Found in abrasive and diamond discs.

- Micro-Edge: Reduces material waste and improves cutting efficiency, perfect for decorative finishes in diamond discs.

- Round Edge: Suitable for lighter applications, reducing the risk of surface damage.

- Diamond Edge: Designed for high-precision cutting with minimal kerf, common in diamond discs.

Choose the right edge geometry based on your project needs. For instance, a micro-edge disc is great for reducing waste and ensuring clean cuts when working on a delicate countertop.

Selection Criteria for Stone Cutting Discs

Consider these key factors to get the best disc for your project:

- Durability: High-quality discs last longer, minimizing downtime and maintenance. Look for discs with a long lifespan.

- Cutting Speed: Determine based on stone type. Abrasive discs are faster, but diamond discs offer higher precision.

- Precision: Opt for sharp edges and well-designed working principles to ensure clean and even cuts, especially crucial for harder stones.

- Chip Removal Efficiency: Discs with high abrasivity or specialized edge geometries (e.g., micro-edges) improve chip removal, reducing material waste and dust.

For example, if you need to cut a thick stone wall, a stiffer disc with a V-edge might be more suitable. If youre working on a thin decorative stone, a micro-edge disc would minimize waste.

Factors Influencing the Selection of Stone Cutting Discs

Several factors impact your disc selection:

1. Cutting Depth: Thicker cuts may require stiffer discs or slower RPMs. Adjust based on your project needs.

2. Feed Rate (RPM): Higher RPMs increase cutting efficiency but may shorten the discs lifespan. Follow manufacturer recommendations.

3. Material Feed: Proper feeding ensures optimal performance. Excess or insufficient material can lead to uneven cuts or damage.

4. Wear and Tear: Regular maintenance, like disc dressing and checking for defects, extends its lifespan.

For instance, if youre cutting a layer of mortar in a large stone wall, adjusting your RPM and feed rate can help maintain efficiency and minimize waste.

Applications and Case Studies

Stone cutting discs are versatile and used in various projects:

- Case Study 1: A homeowner installing a marble countertop selects a diamond disc for high precision and durability, achieving a smooth, even finish.

- Case Study 2: A mason working on a large stone wall uses abrasive-bonded discs for efficiency, ensuring a clean cut and minimal waste.

These examples demonstrate the importance of selecting the right disc for your specific application.

Conclusion and Final Thoughts

Selecting the right stone cutting disc is a smart investment in your projects success. By understanding the working principles, considering material compatibility and edge geometry, and balancing key selection criteria, you can achieve better outcomes.

Stone cutting discs are versatile tools for both professional masons and DIY enthusiasts. Prioritize durability, precision, and chip removal efficiency to get the best results. With the right disc and techniques, you can achieve stunning results and enjoy a well-crafted project.

This version is concise, clear, and engaging, making it easier for readers to understand and apply the information.