Global Leading Diamond Tool Manufacturer.

What is a Stone Cutting Disc and What Factors Should You Consider?

In the world of construction and renovation, precision and durability are paramount. One crucial tool that plays a pivotal role in achieving these goals is the stone cutting disc. These specialized discs are designed to cut through a variety of hard stones, from granite and marble to quartz and limestone. Understanding what stone cutting discs are and the factors to consider when choosing them can significantly enhance the efficiency and longevity of your projects.

What is a Stone Cutting Disc?

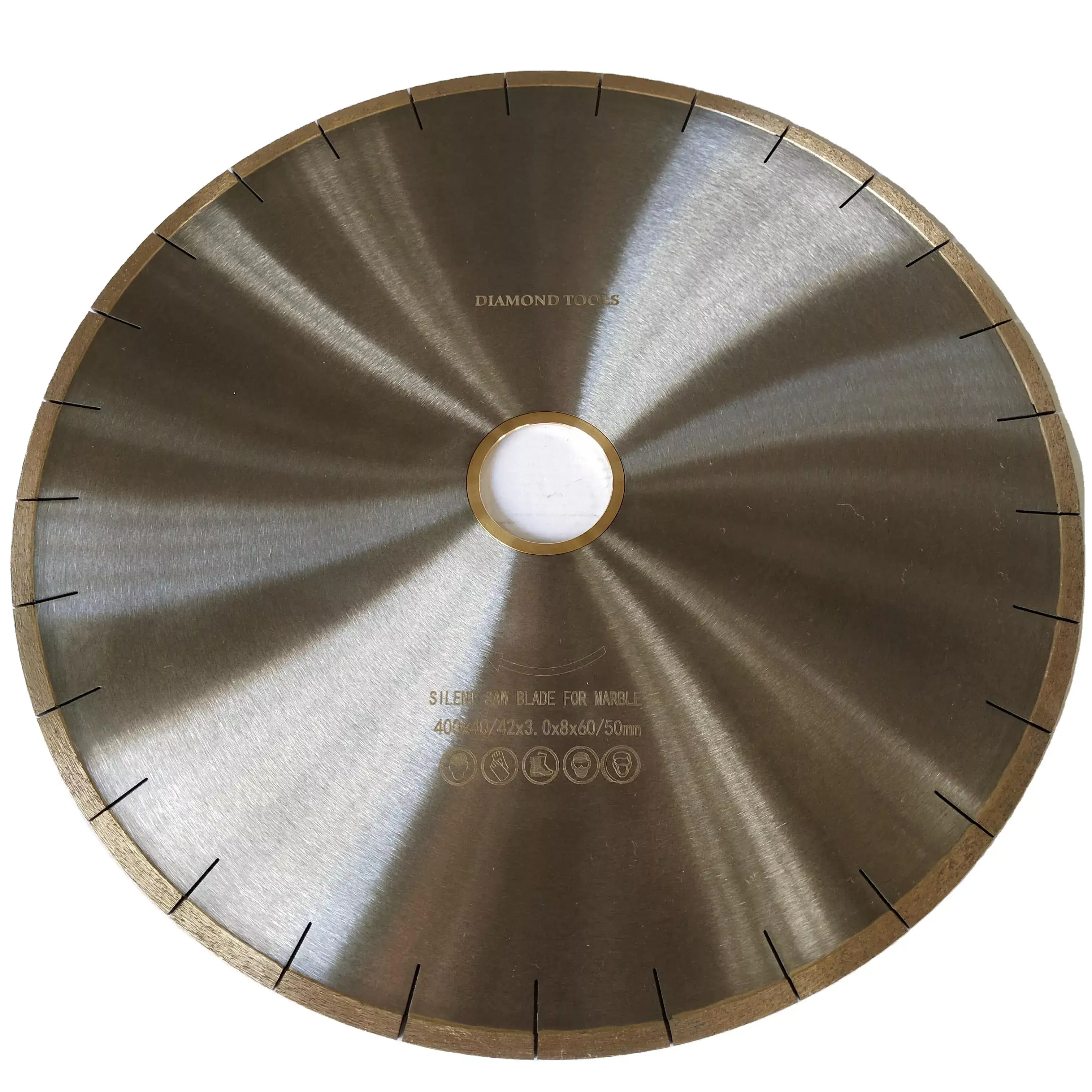

A stone cutting disc is a circular disc made from a combination of abrasive materials, typically a diamond matrix bonded to a metal or resin core. These discs are used in angle grinders and other specialized cutting tools to slice through hard stone materials with precision and efficiency. The discs come in various types, including diamond-based and metal-bonded, each designed to handle different stone types and applications.

Different materials are used in making stone cutting discs, including:

- Diamond: Diamond is the hardest natural material known, making it ideal for cutting through abrasive and hard stones. Diamond discs can be further categorized into various grit sizes, each suited for specific applications.

- Metal Bond: Metal-bonded discs are composed of a metal matrix that holds the abrasive particles together. These discs are less expensive and can be used on softer stones, but they may not be as durable as diamond discs.

How Does a Stone Cutting Disc Work?

The cutting process of a stone cutting disc involves a combination of pressure and vibration. When the disc is rotated at high speeds, the abrasive particles embedded in the matrix come into contact with the stone, causing friction and creating a cutting action. This process can be influenced by several factors, including:

- Speed: Proper speed is essential to ensure efficient cutting while preventing overheating and damage to the disc.

- Pressure: Applying the right amount of pressure can enhance the cutting performance but too much pressure can cause premature wear and tear.

- Water Usage: Using water during the cutting process helps to cool the disc and stone, preventing overheating and maintaining cutting efficiency.

What Factors Should You Consider When Selecting a Stone Cutting Disc?

When choosing a stone cutting disc, several key factors must be considered to ensure the best outcome for your project. These factors include:

Material Durability:

Choosing the right material for the stone type is crucial. For instance, diamond discs are highly durable and suitable for cutting through extremely hard and abrasive stones, making them ideal for materials like granite and marble. Metal-bonded discs, while less durable, are more budget-friendly and suitable for softer stones like limestone.

Disk Diameter and Thickness:

The diameter and thickness of the disc affect its cutting capacity and stability. A larger diameter disc generally offers more cutting power and can handle larger stones more effectively. Thicker discs provide better stability and resistance to chipping, which is beneficial for heavy-duty cutting tasks.

Practical Applications of Stone Cutting Discs

Stone cutting discs find extensive use in various industries due to their versatility and efficiency. Here are a few examples of successful applications:

- Construction: Professionals use stone cutting discs to cut through large slabs of granite or marble for countertops, flooring, and other architectural elements.

- Renovation: In renovation projects, stone cutting discs are used to modify existing stone structures, such as slicing down granite countertops or removing old marble tiles.

Comparison of Different Stone Cutting Discs

When comparing standard and premium stone cutting discs, it's important to consider factors like longevity, cutting performance, and cost-effectiveness. Premium discs, made with higher-quality materials and construction, often provide better performance and longer life. However, they come at a higher price. Standard discs, on the other hand, offer a balance of performance and cost without sacrificing too much quality.

Maintenance and Care Tips for Stone Cutting Discs

Proper maintenance and care can extend the lifespan of your stone cutting discs. Here are a few tips:

- Proper Storage: Store discs in a dry place to prevent moisture damage.

- Handling: Handle discs with care to avoid chipping or cracking.

- Lifespan Techniques: Replace the disc when it shows signs of wear, such as dull edges or excessive heat.

Future Trends in Stone Cutting Disc Technology

The future of stone cutting disc technology looks promising, with ongoing innovations in materials and design. New materials are being developed to enhance cutting performance and durability. Advanced manufacturing techniques are also improving the overall quality and efficiency of these discs. In the coming years, we may see even more durable and cost-effective options that can handle a wider range of applications.

Conclusion

In conclusion, stone cutting discs are indispensable tools in construction and renovation, offering precision and efficiency. By understanding the key factors to consider when selecting these discs, you can ensure that your projects are completed with the highest level of quality and performance. Whether you are a professional contractor or a do-it-yourself enthusiast, taking the time to choose the right disc can make a significant difference in the outcome of your work.