Global Leading Diamond Tool Manufacturer.

Why Safety Is Crucial for Stone Cutting Discs

In the bustling world of construction and manufacturing, stone cutting discs are indispensable tools. These discs, designed to slice through hard materials like stone, concrete, and masonry, are a mainstay for professionals. Despite their efficiency, their use poses significant risks. According to industry statistics, accidents involving stone cutting discs account for a substantial portion of workplace injuries, often leading to higher accident rates due to psychological impacts. This underscores the critical importance of stringent safety protocols to protect users and ensure smooth operations.

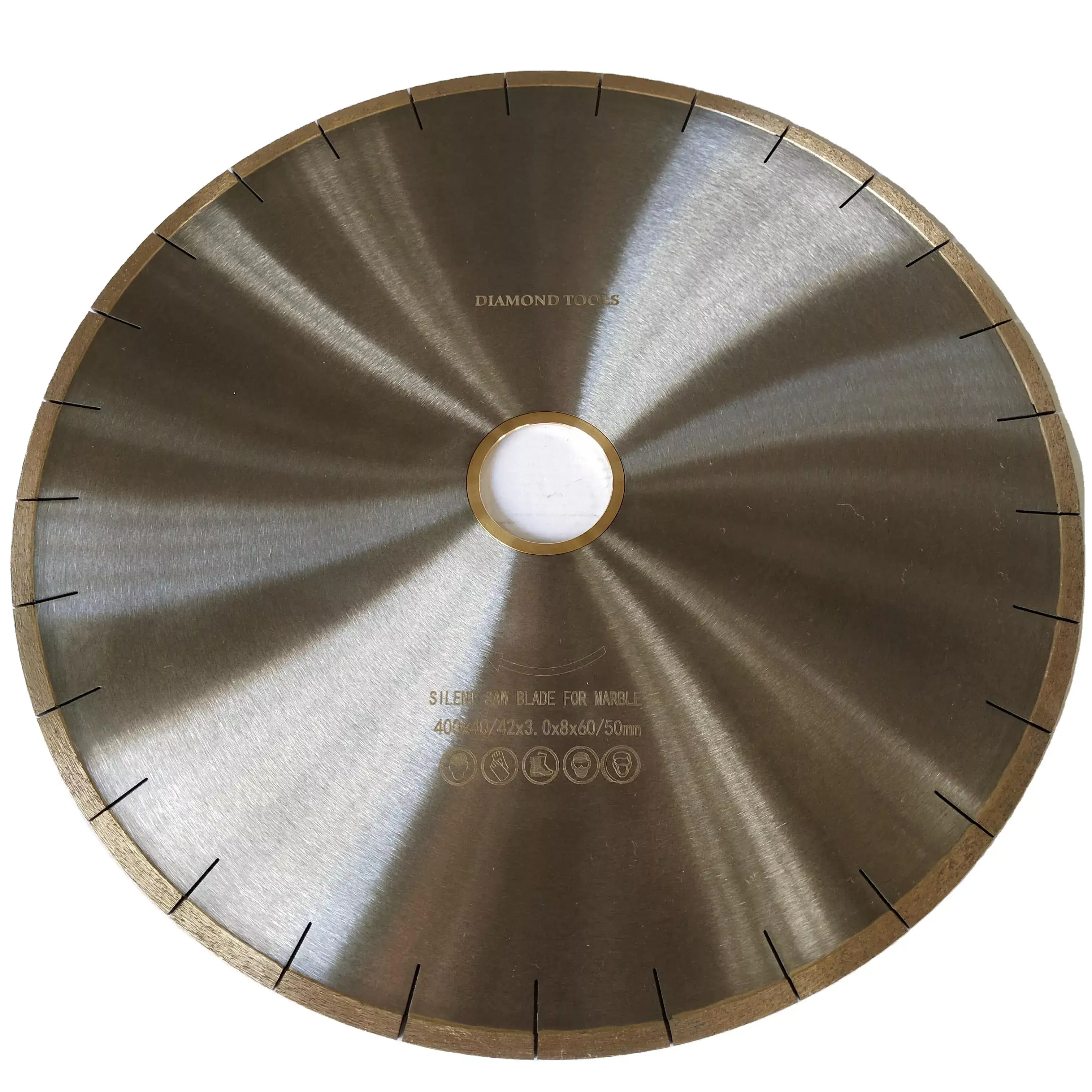

Understanding Stone Cutting Discs: Function and Risks

Stone cutting discs are circular abrasives engineered to cut through tough materials. These tools are essential for tasks such as shaping stones and cutting tiles. However, improper usage can lead to severe dangers, including disc shattering, flying debris, and even catastrophic bodily harm. Understanding these risks is crucial for anyone handling these powerful tools. For instance, a single instance of disc shattering can result in critical injuries, which can then create a psychological spiral of fear and caution among workers, leading to a higher incidence of accidents in the future.

Safety Protocols for Stone Cutting Discs: Essential Guidelines

Ensuring the safe use of stone cutting discs involves adhering to several key protocols. First and foremost, operators must wear appropriate personal protective equipment (PPE), such as eye protection, gloves, and hearing protection, to shield against debris and noise. Inspecting the disc for cracks or damage before use is another critical step. Proper mounting and securing of the disc on the tool also prevent accidents. Additionally, maintaining a clean and organized workspace minimizes risks. These practices, coupled with thorough training, form the cornerstone of safe stone cutting disc operation.

Case Study: Consequences of Neglecting Safety

Consider a scenario where a construction worker, in a rush to meet deadlines, neglects to inspect a stone cutting disc for damage. During operation, the disc shatters, sending shards flying and causing severe injury. This incident not only affects the individual but also sets a concerning precedent for the entire workforce. It can lead to an increase in workplace injuries as fear and caution become the new norm, potentially creating a vicious cycle. Furthermore, the business faces costly downtime and potential legal repercussions, highlighting the broader impact of neglecting safety protocols.

Comparative Analysis: Safe vs. Unsafe Practices

A closer examination of stone cutting operations reveals significant differences between safe and unsafe practices. Safe practices include regular maintenance checks, using the correct disc for the material, and operating the tool at the recommended speed. In contrast, unsafe practices often involve ignoring signs of wear, using inappropriate equipment, and neglecting PPE. Adhering to safety measures not only minimizes risks but also enhances operational efficiency, ensuring projects proceed without interruptions.

Innovations in Stone Cutting Disc Safety: Emerging Trends

The industry is witnessing a transformation in safety with new innovations. Advances in disc materials and design now offer increased durability, reducing the risk of shattering. Manufacturers are also incorporating safety features such as anti-kickback mechanisms and vibration reduction technologies. These innovations promise a safer future, enhancing both safety and productivity in stone cutting operations.

Prioritizing Safety for Optimal Results

In conclusion, prioritizing safety in the use of stone cutting discs is not just a matter of compliance but a critical lifeline for both individuals and businesses. The risks associated with improper handling are real and can be severe, impacting not only the immediate consequences but also the broader psychological and operational environments. By focusing on safe practices and embracing emerging safety technologies, construction professionals can ensure effective and secure operations. As the industry evolves, integrating these safety measures will be crucial for maintaining the strength and reliability of stone cutting disc tools, fostering a safer and more efficient work environment.