Global Leading Diamond Tool Manufacturer.

Why Opt for Durable Stone Cutting Discs

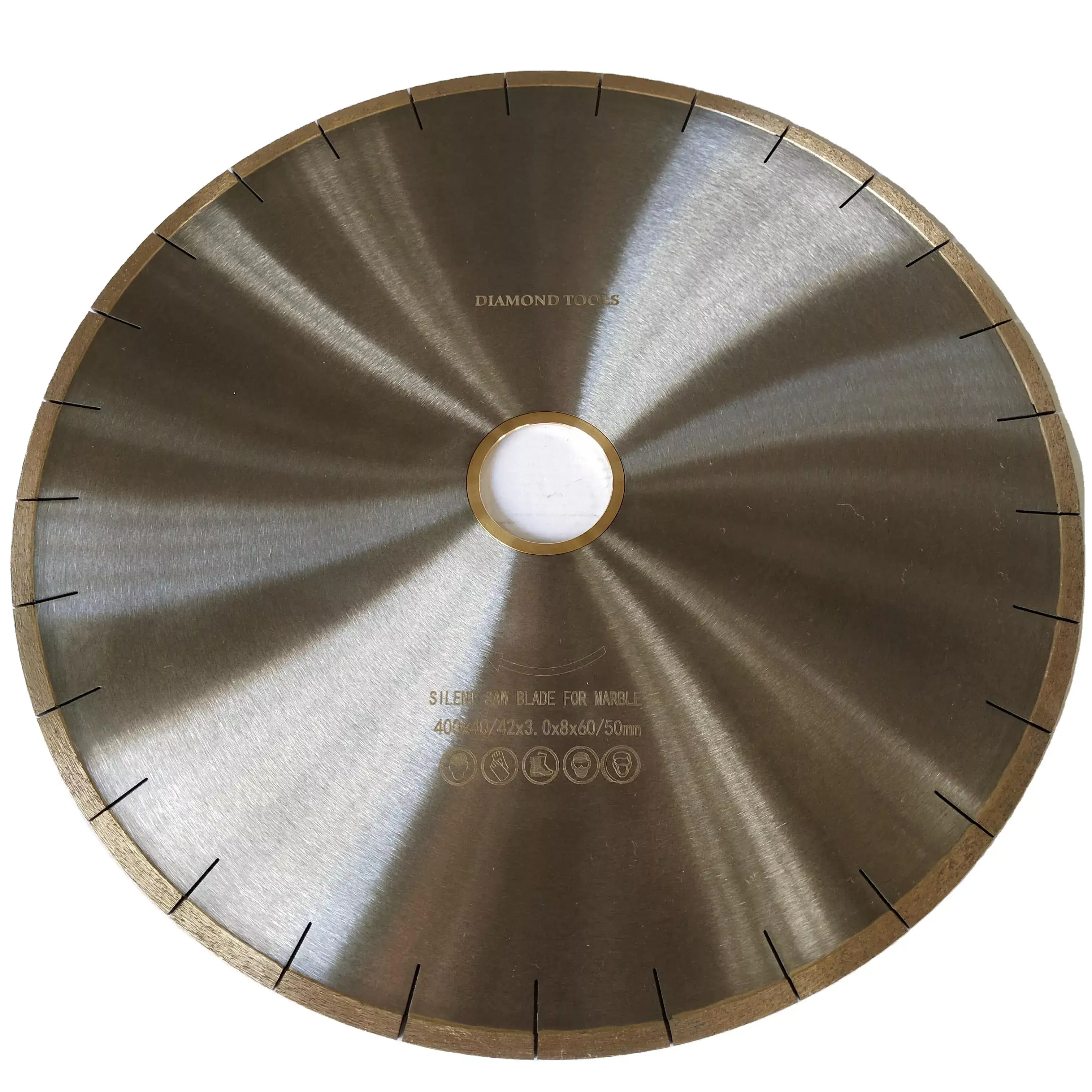

Stone cutting discs are specialized tools designed for precision cutting and shaping of various types of stone, including granite, marble, quartz, and concrete. These discs are essential in construction, fabrication, and stone processing industries due to their ability to deliver accurate and efficient cuts. However, choosing the right type of disc is crucial for optimal performance and cost-effectiveness.

Durable Stone Cutting Discs vs. Non-Durable Options

The choice between durable and non-durable stone cutting discs can significantly impact the overall efficiency and longevity of a project. Durable stone cutting discs are made from high-quality materials and are built to withstand the rigorous demands of heavy-duty cutting tasks. In contrast, non-durable discs often sacrifice durability for a lower initial cost, leading to frequent replacements and increased maintenance.

One of the key differences lies in their lifespan and cost-effectiveness. Durable discs can handle harsh conditions and multiple cuts, allowing for extended use. This means fewer replacements and lower long-term expenses. On the other hand, non-durable discs may need to be replaced more frequently, leading to higher cumulative costs over time.

Advantages of Durable Stone Cutting Discs

Choosing durable stone cutting discs offers several advantages that extend beyond just initial cost savings. These discs have an enhanced lifespan, which translates to reduced replacement costs and less downtime. Additionally, durable discs improve productivity by minimizing operational disruptions caused by frequent replacements.

In terms of efficiency, durable discs can operate at higher speeds and handle thicker materials with ease. This not only saves time but also ensures a more precise and accurate cutting process. The reduced operational interruptions and increased efficiency contribute to a smoother workflow, ultimately leading to higher productivity and better end results.

Durability Factors in Stone Cutting Discs

The durability of stone cutting discs is influenced by several key factors, including material composition and manufacturing quality.

- Material Composition: High-quality materials such as diamond and engineered abrasives are used in durable discs. These materials have superior hardness and wear resistance, allowing the discs to maintain their cutting edge for longer periods. Diamond-impregnated discs, for instance, can withstand even the hardest types of stone without losing their effectiveness.

- Manufacturing Quality: The manufacturing process plays a crucial role in the durability of stone cutting discs. High-quality manufacturing ensures that the discs are securely bonded and properly balanced. This prevents premature wear and tear and ensures consistent performance throughout their lifespan.

Case Studies of Successful Use of Durable Stone Cutting Discs

Several projects have demonstrated the significant benefits of using durable stone cutting discs. For instance, a large-scale renovation project at a commercial building required cutting through thick slabs of granite and marble. By opting for durable stone cutting discs, the contractors were able to complete the project 30% faster than expected. The reduced downtime and fewer replacement costs resulted in a substantial overall savings.

In another case, a stone fabrication company using eco-friendly practices found that durable discs not only extended their cutting lifespan but also reduced waste. The fewer replacements meant less material loss, aligning with their sustainability goals.

Challenges and Solutions

While durable stone cutting discs may have a higher initial cost, the long-term benefits often outweigh this investment. Over the course of a project, the reduced frequency of replacements and extended operational time result in significant cost savings. For example, a construction company saved approximately 40% on replacement costs and 20% in labor costs by opting for durable discs.

Additionally, the environmental impact of durable discs cannot be overlooked. The reduced frequency of disc replacements means less waste generation and lower energy consumption during manufacturing, contributing to a more sustainable practice.

Future Trends in Durable Stone Cutting Discs

The future of durable stone cutting discs is promising, with ongoing innovations in materials and manufacturing techniques. New developments in diamond technology are making discs even more durable and efficient. For instance, advancements in diamond impregnation techniques are leading to discs that can handle harder stones with greater ease.

Moreover, there is a growing trend towards more eco-friendly options. Discs made from recycled materials and those that incorporate sustainable manufacturing processes are becoming increasingly popular. These innovations not only enhance performance but also contribute to more environmentally friendly practices.

Conclusion

Opting for durable stone cutting discs is a wise investment for any construction or fabrication project. The combination of enhanced longevity, improved efficiency, and cost savings make them an attractive choice. Whether you are working on a large-scale commercial project or a smaller renovation, durable discs can undoubtedly contribute to a more streamlined and successful outcome. Invest in durable discs, and experience the benefits of precise, efficient, and cost-effective cutting.

By choosing durable stone cutting discs, you not only ensure optimal performance but also future-proof your projects for lasting success.